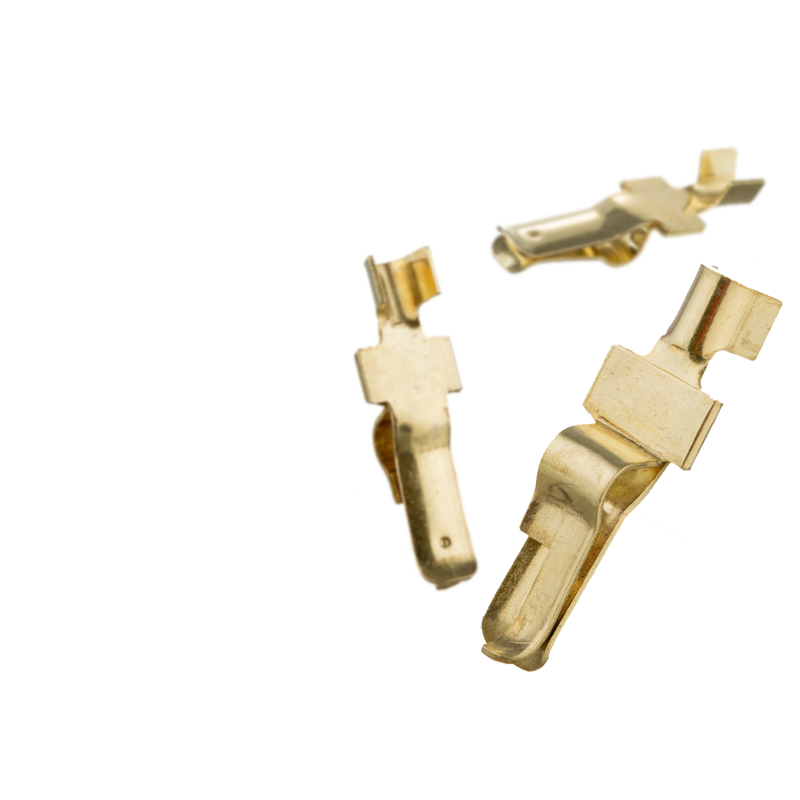

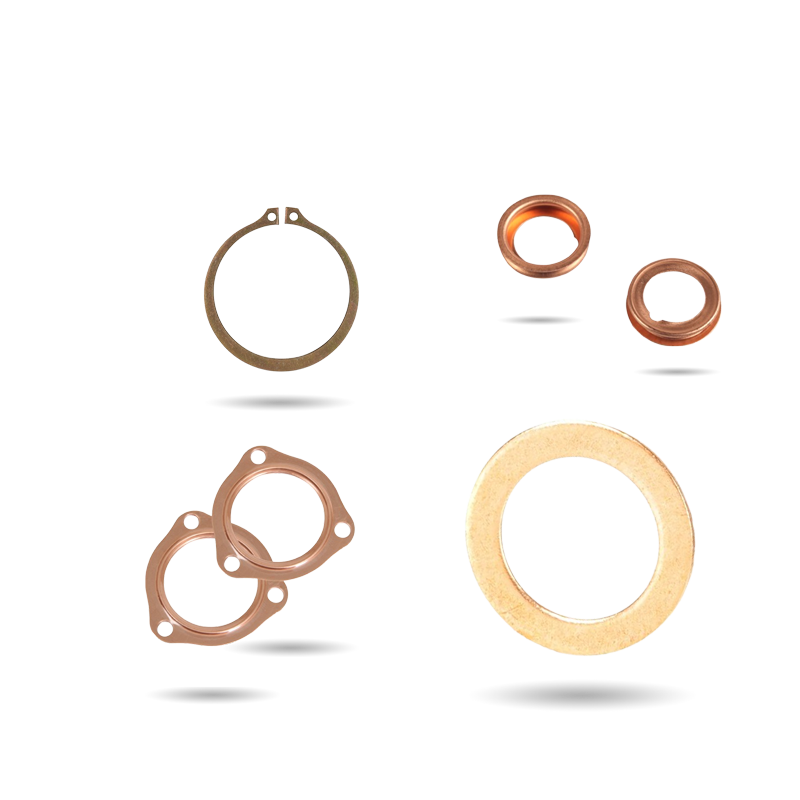

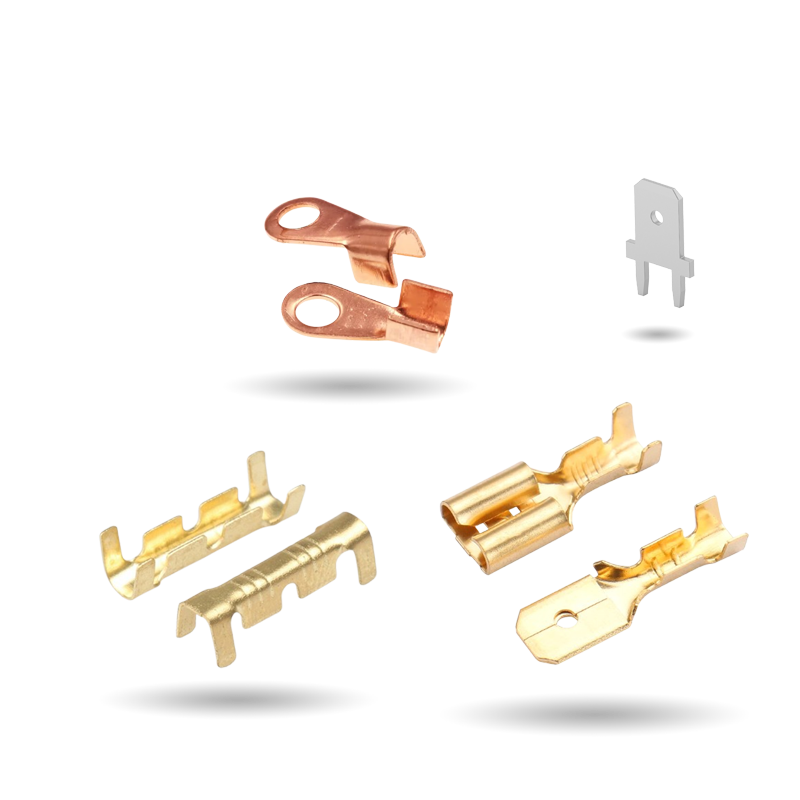

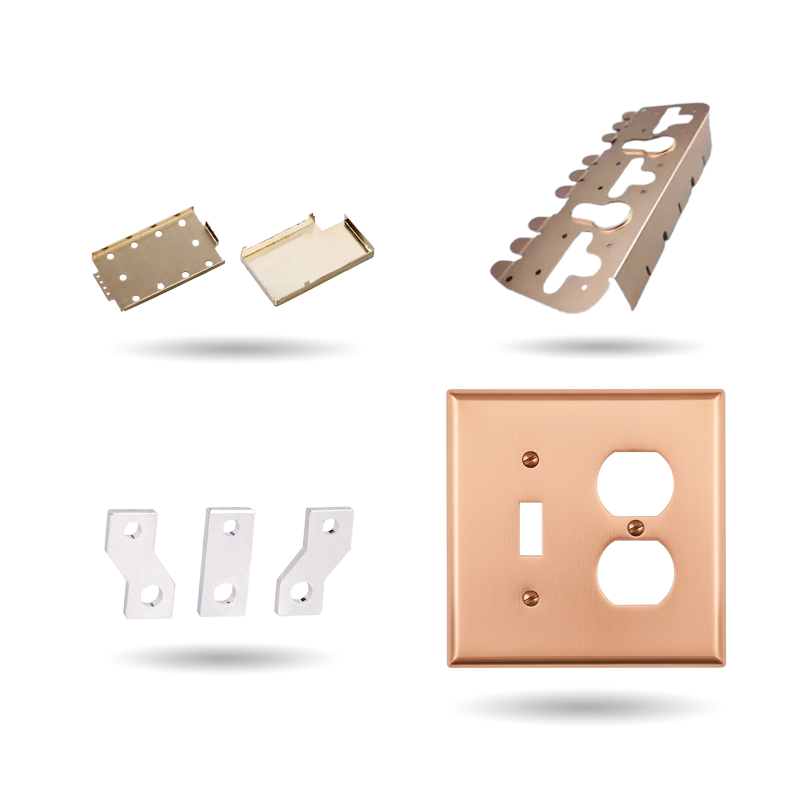

Product Detail

| Product Code | – | Material | – |

| Manufacturing Technology | Stamping | Minimum Order Quantity | – |

| Surface Treatment | – | Thickness (mm) | – |

| Production Standards | ROHS, ISO 9001 | Tolerance (mm) | – |

To receive a quotation and detailed consultation on products and technical specifications, please contact:

| Mr. Doan Thanh Tung (David) International Sales 📞+84 975 441 115 ✉️ tung.doan@dulico.vn | Mr. Nguyen Trong Duy (LEO) Director ✉️ duy.nguyen@dulico.vn |