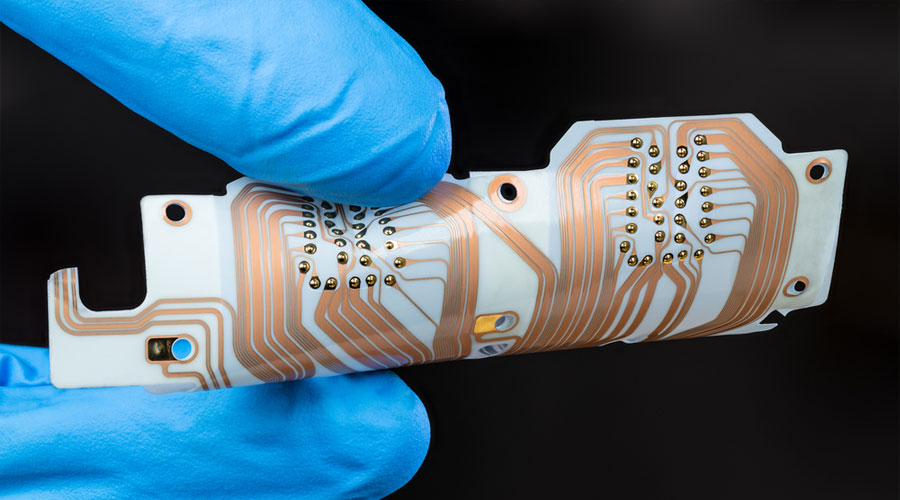

Copper strip/plate

COPPER STRIP

With an automated and modern production line, alongside a continuous improvement of technology, DULICO aims to be a pioneer in the casting and rolling of copper, also known as copper strip, in Vietnam. DULICO has successfully produced with 99.90% pure copper, available in various sizes and thicknesses.

In addition to the inherent properties of pure copper, such as stability, high electrical conductivity, and good thermal conductivity, Dulico’s copper strips also ensure stable thickness, uniform hardness, bright surface, and flat, non-warped, and non-bent strips.

With properties that make it easy to process, weld, and plate, and high corrosion resistance, copper strip are widely used in various industries, with special applications in the electrical and electronics sectors.

COPPER STRIP CERTIFICATIONS

Machinery & Equipment

System Details for Machinery & Equipment

| MACHINERY & EQUIPMENT | QUANTITY |

|---|---|

| Casting Line – China | 3 |

| Surface Milling Line – China | 1 |

| Rough & Finish Rolling Line – China | 2 |

| Surface Cleaning Line – China | 2 |

| Copper Annealing Furnace – China | 2 |

| Splitting Line – China | 2 |

| QC INSPECTION | |

| Copper Analyzer – Spectro – Germany | 1 |

| HV Hardness Analyzer – FUTURE-TECH – Japan | 1 |

| HRB Hardness Analyzer – China | 1 |

| Roughness Analyzer – Mitutoyo – Japan | 1 |

| Electronic Tensile Strength Testing Machine – China | 1 |

| Panme – Mitutoyo – Nhật Bản | 10 |

| Caliper – Mitutoyo – Japan | 30 |

| Automatic Copper Strip Thickness Gauge – China | 2 |

APPLICATIONS

Applications of Copper Strip

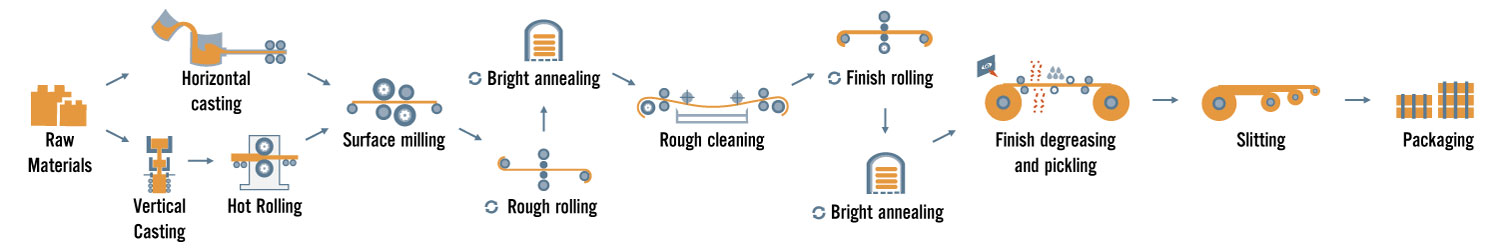

Produktionsprozess

Production Process Detail

Copper Strip Technical Specifications

Alloy Grade Cross-Reference Table

| # | Japan | USA | UK / EU | Germany | China | ||

|---|---|---|---|---|---|---|---|

| JIS | ASTM | CDA | EN | DIN | Werkstoff Number | GB | |

| 1 | C1020 | C10200 | CDA102 | CW008A | OF-Cu | 20.040 | TU1 |

| 2 | C1100 | C11000 | CDA110 | CW004A | E-Cu | 20.065 | T2 |

| 3 | C1220 | C12200 | CDA122 | CW024A | SF-Cu | 20.090 | TP2 |

Chemical Composition

| # | Alloy Grade | Chemical Composition | Dimensional Specifications | |||||

|---|---|---|---|---|---|---|---|---|

| JIS | DIN | Copper(%) | Oxygen(%) | Zn/Pb/Fe | Impurities | Thickness (mm) | Width (mm) | |

| 1 | C1020 | OF-Cu | ≥99.96 | ≤0.001 | ≤0.01 | – | 0.2-10 mm (0.00787 – 0.3937 in) | 06 – 450 mm (0.236–17.717 in) |

| 2 | C1100 | E-Cu | ≥99.90 | ≤0.04 | ≤0.05 | – | ||

| 3 | C1220 | SF-Cu | ≥99.90 | 0.02–0.04 | ≤0.05 | – | ||

Physical & Mechanical Properties

| JIS | DIN | Temper | Vickers Hardness (HV) | Elongation (%) | Tensile Strength (MPa) | Bending Angle |

|---|---|---|---|---|---|---|

| C1020 | OF-Cu | O | – | ≥20 | ≥195 | 180° |

| 1/4H | 55–100 | ≥15 | 215–285 | 180° | ||

| 1/2H | 75–120 | ≥10 | 235–315 | 180° | ||

| H | ≥80 | – | ≥275 | 90° | ||

| C1100 | E-Cu | O | – | ≥20 | ≥195 | 180° |

| 1/4H | 55–100 | ≥15 | 215–285 | 180° | ||

| 1/2H | 75–120 | ≥10 | 235–315 | 180° | ||

| H | ≥80 | – | ≥275 | 90° | ||

| C1220 | SF-Cu | O | – | ≥20 | ≥195 | 180° |

| 1/4H | 55–100 | ≥15 | 215–285 | 180° | ||

| 1/2H | 75–120 | ≥10 | 235–315 | 180° | ||

| H | ≥80 | – | ≥275 | 180° |

FAQ OF COPPER STRIP

What is copper strip ?

It is a product made from pure copper, typically manufactured by rolling copper into thin sheets and then coiling it for easy transportation and use in various applications.

Is the production process of copper strip complicated ?

Yes, the production process is quite complex and involves several steps such as melting, casting, rolling, and splitting. Each step requires strict quality control to ensure the final product meets the required standards.

How is copper C1100 different from other types of copper ?

C1100 has a copper higher purity level, offering better electrical conductivity and superior workability compared to many other copper types.

Can it be ordered to specification?

Yes, DULICO provides to customer specifications, including options for thickness, width, hardness, and other parameters to meet the specific needs of clients.

What is the delivery time orders ?

Delivery time depends on the order quantity and specific customer requirements. DULICO is committed to fast delivery, typically within 10 to 20 days after the order is placed

To receive a quotation and detailed consultation on products and technical specifications, please contact:

| Mr. Doan Thanh Tung (David) International Sales 📞+84 975 441 115 ✉️ tung.doan@dulico.vn | Ms. Trinh Ngoc Khue (Lucy) International Sales 📞+84 984 805 505 ✉️ lucy@dulico.vn | Mr. Nguyen Trong Duy (LEO) Director ✉️ duy.nguyen@dulico.vn |