Brass strip & plate

BRASS STRIP

Dulico is a pioneering enterprise in Vietnam specializing in the casting and rolling of brass strips — also known as brass foil or brass bands — using modern and highly automated production lines.

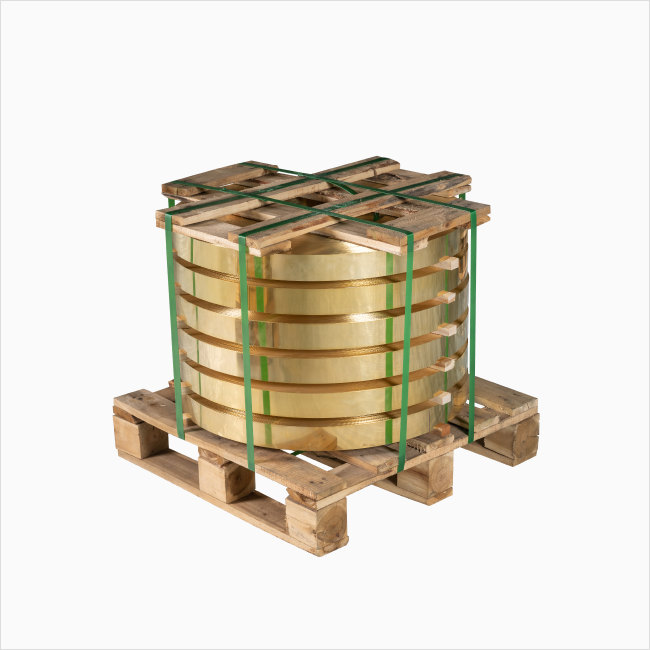

Brass strip is an alloy of copper and zinc in specific ratios, rolled into thin sheets and wound into coils of various sizes and thicknesses for easy transport and customization according to customer requirements.

In addition to the general properties of high electrical and thermal conductivity, good ductility, and excellent mechanical strength, Dulico brass stands out for its superior flatness, consistent thickness, uniform hardness, and clean, bright surface quality.

BRASS STRIP CERTIFICATIONS

PRODUCTION MACHINERY & EQUIPMENT SYSTEM

Machinery & Equipment System Detail

| MACHINERY & EQUIPMENT | QUANTITY |

|---|---|

| Casting Line – China | 3 |

| Surface Milling Line – China | 1 |

| Rough & Finish Rolling Line – China | 2 |

| Surface Cleaning Line – China | 2 |

| Copper Annealing Furnace – China | 2 |

| Splitting Line – China | 2 |

| QC INSPECTION | |

| Copper Analyzer – Spectro – Germany | 1 |

| HV Hardness Analyzer – FUTURE-TECH – Japan | 1 |

| HRB Hardness Analyzer – China | 1 |

| Roughness Analyzer – Mitutoyo – Japan | 1 |

| Electronic Tensile Strength Testing Machine – China | 1 |

| Panme – Mitutoyo – Japan | 10 |

| Caliper – Mitutoyo – Japan | 30 |

| Automatic Copper Strip Thickness Gauge – China | 2 |

APPLICATIONS

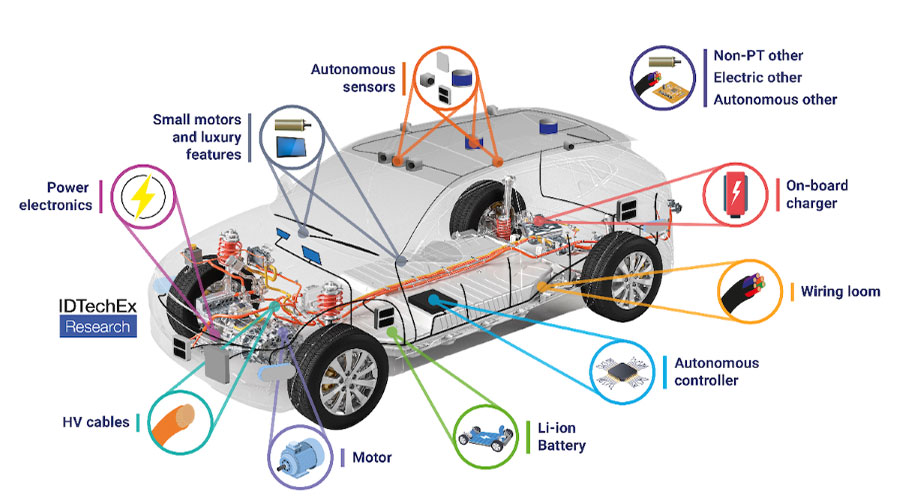

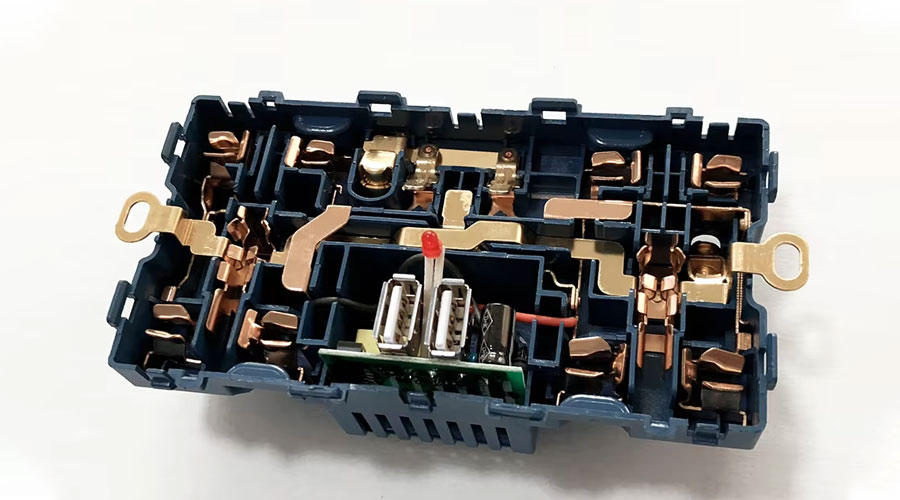

Due to its inherent properties, brass is widely applied across multiple industries. Specifically, it plays a crucial role in fields such as electrical systems, home electronics, interior and exterior decoration, the automotive sector, and several other areas

Applications Detail

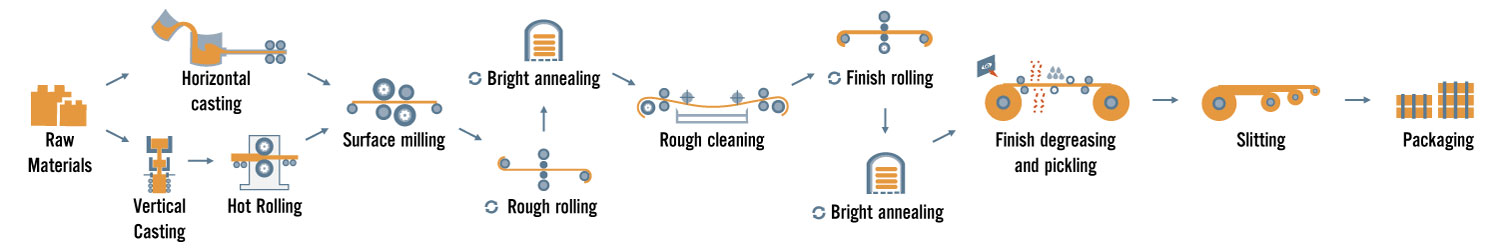

PRODUCTION PROCESS

Brass Strip Technical Specifications

Alloy Grade Cross-Reference Table

| # | Japan | USA | UK / EU | Germany | China | ||

|---|---|---|---|---|---|---|---|

| JIS | ASTM | CDA (Copper Development Association) | EN | DIN | Werkstoff Number | GB | |

| 1 | C2400 | C24000 | CDA240 | CW503L | CuZn20 | 2.0240 | H80 |

| 2 | C2600 | C26000 | CDA260 | CW505L | CuZn30 | 2.0265 | H70 |

| 3 | C2680 | C26800 | CDA268 | CW506L | CuZn33 | 2.0280 | H68 |

| 4 | C2720 | C27200 | CDA272 | CW508L | CuZn37 | 2.0321 | H63 |

| 5 | C2801 | C28000 | CDA280 | CW509L | CuZn40 | 2.0360 | H62/H59 |

Chemical Composition

| # | Alloy Grade | Chemical Composition | Dimensional Specifications | ||||||

|---|---|---|---|---|---|---|---|---|---|

| JIS | DIN | Copper (%) | Zinc (%) | Lead (%) | Iron (%) | Impurities | Thickness (mm) | Width (mm) | |

| 1 | C2400 | CuZn20 | 79.0–81.0 | Remain | ≤0.03 | ≤0.05 | ≤0.3 | 0.2-10 mm (0.00787 – 0.3937 in) | 06 – 450 mm (0.236–17.717 in) |

| 2 | C2600 | CuZn30 | 68.5–71.5 | Remain | ≤0.03 | ≤0,05 | <0,3 | ||

| 3 | C2680 | CuZn33 | 63.5–65.0 | Remain | ≤0.03 | ≤0,05 | <0,3 | ||

| 4 | C2720 | CuZn37 | 62.0–65.0 | Remain | ≤0.05 | ≤0.07 | ≤0.3 | ||

| 5 | C2801 | CuZn40 | 59.0–62.0 | Remain | ≤0.1 | ≤0,05 | <0,3 | ||

Physical & Mechanical Properties

| JIS | DIN | Temper | Vickers Hardness (HV) | Elongation (%) | Tensile Strength (MPa) | Bending Angle |

|---|---|---|---|---|---|---|

| C2400 | CuZn20 | O | – | ≥44 | ≥255 | 180° |

| 1/4H | – | ≥30 | 295–375 | 180° | ||

| 1/2H | – | ≥25 | 325–400 | 180° | ||

| H | – | – | ≥375 | 180° | ||

| C2600 | CuZn30 | O | – | ≥35 | ≥275 | 180° |

| 1/4H | 75–125 | ≥30 | 325–420 | 180° | ||

| 1/2H | 85–145 | ≥23 | 355–450 | 180° or W | ||

| 3/4H | 95–160 | ≥10 | 375–490 | 180° or W | ||

| H | 105–175 | – | 410–540 | 180° or W | ||

| EH | 145–195 | – | 520–620 | – | ||

| SH | 165–215 | – | 570–670 | – | ||

| C2680 | CuZn33 | O | – | ≥35 | ≥275 | 180° |

| 1/4H | 75–125 | ≥30 | 325–410 | 180° | ||

| 1/2H | 85–145 | ≥28 | 355–440 | 180° or W | ||

| 3/4H | 95–165 | ≥10 | 375–490 | 180° or W | ||

| H | 105–175 | – | 410–540 | 180° or W | ||

| EH | 145–195 | – | 520–620 | – | ||

| SH | 165–215 | – | 570–670 | – | ||

| ESH | ≥180 | – | ≥620 | – | ||

| C2720 | CuZn37 | O | – | ≥40 | ≥275 | 180° |

| 1/4H | 75–125 | ≥35 | 325–410 | 180° | ||

| 1/2H | 85–145 | ≥28 | 355–440 | 180° | ||

| H | ≥130 | – | ≥470 | 90° | ||

| C2801 | CuZn40 | O | – | ≥35 | ≥325 | 180° |

| 1/4H | 85–145 | ≥35 | 355–440 | 180° | ||

| 1/2H | 105–160 | ≥15 | 410–490 | 180° | ||

| H | ≥130 | – | ≥470 | 90° |

FAQs

What is brass strip?

It’s an alloy of copper and zinc, typically produced by rolling and coiling into rolls for easy transportation and use in various applications.

How do brass strip differ from other types of copper?

In addition to differences in chemical composition, brass strip are malleable, easy to process, highly durable, resistant to corrosion, and have a bright yellow color. This makes them ideal for producing aesthetically pleasing components, accessories, and parts.

Is the production process of brass strip complicated?

Yes, the production process involves multiple steps such as melting, casting, rolling, and splitting. Each step requires strict quality control.

Can brass strip be custom ordered?

Yes, DULICO offers custom production services based on customer specifications, including options for thickness, width, and alloy composition to meet specific application requirements.

What is the delivery time for brass strip orders?

The delivery time depends on the order quantity and specific customer requirements. DULICO is committed to fast delivery, typically within 10-20 days after the order is placed.

To receive a quotation and detailed consultation on products and technical specifications, please contact:

| Mr. Doan Thanh Tung (David) International Sales 📞+84 975 441 115 ✉️ tung.doan@dulico.vn | Ms. Trinh Ngoc Khue (Lucy) International Sales 📞+84 984 805 505 ✉️ lucy@dulico.vn | Mr. Nguyen Trong Duy (LEO) Director ✉️ duy.nguyen@dulico.vn |