Aluminum Sheet & Strip

DULICO Aluminum Sheet & Strip

DULICO supplies Aluminum Sheet & Strip manufactured and quality-controlled in accordance with EN, ASTM, and JIS standards. Each batch ensures high dimensional precision, excellent surface stability, and superior uniformity required for high-volume industrial applications.

With a comprehensive range of alloy grades, DULICO’s aluminum sheet and strip products are optimized for stamping, coating, anodizing, forming, and component fabrication across diverse industries.

For customers seeking a reliable and internationally compliant supplier of aluminum sheet and strip, DULICO represents a dependable and long-term partner.

Certifications and Quality Standards

Through stringent control at every stage of the production and conversion processes, DULICO ensures that all aluminum sheet and strip products fully comply with international quality and performance requirements.

Key Characteristics of Aluminum Sheet & Strip

- Lightweight Construction: Specific gravity of approximately 2.7 g/cm³, making aluminum roughly three times lighter than steel.

- Excellent Corrosion Resistance: Forms a stable oxide layer, and can be further enhanced through painting, coating, or anodizing.

- High Ductility and Workability: Suitable for cutting, slitting, bending, stamping, drawing, and welding, enabling compatibility with various fabrication processes.

- Superior Electrical and Thermal Conductivity: Widely used in electrical, electronic, thermal management, and HVAC applications.

- Aesthetic Surface Finish: Ideal for painting, printing, coating, and decorative processing.

- 100% Recyclable: Environmentally friendly and aligned with global sustainability and circular-economy initiatives.

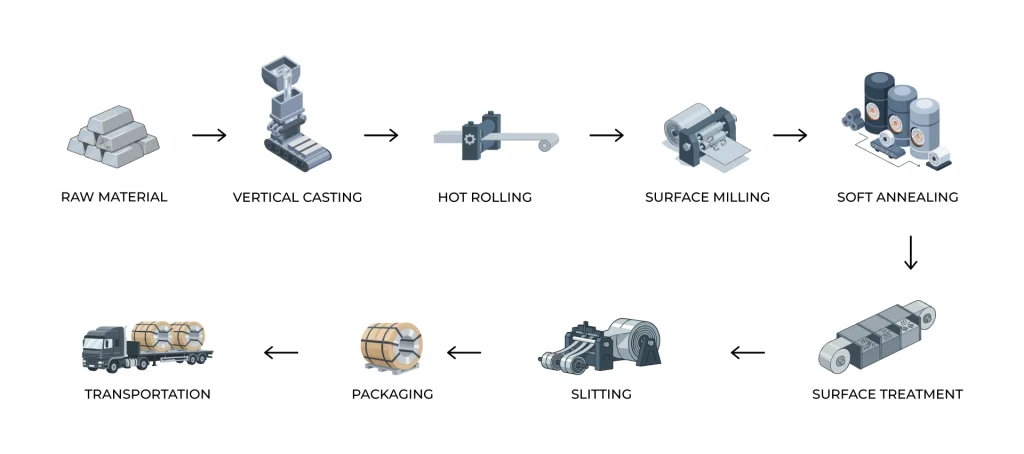

Production Process of Aluminum Sheet & Strip

DULICO sources mother coils from certified mills and converts them into high-precision aluminum strips through a controlled and optimized slitting process.

Applications of Aluminum Sheet & Strip

Thanks to their favorable mechanical and physical properties, DULICO aluminum sheet and strip are extensively utilized across a wide range of industries.

Applications of Aluminum Sheet & Strip

Common Aluminum Alloys

Chemical Composition (Typical)

| GB/T 3880 | JIS H4000 | ASTM B209 | EN 573-3 | Al (%) | Mn (%) | Si + Fe (%) | Other Key Elements |

|---|---|---|---|---|---|---|---|

| 1050 | A1050P | 1050 | EN AW-1050A | ≥ 99,50 | ≤ 0,05 | ≤ 0,65 | Cu, Zn, Mg, Ti ≤ 0,05–0,15 |

| 1100 | A1100P | 1100 | EN AW-1100 | ≥ 99,00 | ≤ 0,05 | ≤ 0,95 | Cu 0,05–0,20 |

| 3003 | A3003P | 3003 | EN AW-3003 | ~98,0 | 1,0–1,5 | ≤ 1,30 | Cu 0,05–0,20; Zn ≤ 0,10 |

| 5052 | A5052P | 5052 | EN AW-5052 | ~96,0 | ≤ 0,10 | ≤ 0,65 | Mg 2,2–2,8; Cr 0,15–0,35 |

| 5754 | A5754P | 5754 | EN AW-5754 | ~95,5 | ≤ 0,50 | ≤ 0,40 | Mg 2,6–3,6; Cr ≤ 0,30 |

| 5083 | A5083P | 5083 | EN AW-5083 | ~93,5 | 0,40–1,0 | ≤ 0,40 | Mg 4,0–4,9; Cr 0,05–0,25 |

| 6061 | A6061P | 6061 | EN AW-6061 | ~96,5 | ≤ 0,15 | ≤ 1,50 | Mg 0,8–1,2; Si 0,4–0,8; Cu 0,15–0,40 |

| 6063 | A6063P | 6063 | EN AW-6063 | ~97,5 | ≤ 0,10 | ≤ 0,95 | Mg 0,45–0,90; Si 0,2–0,6 |

| 8011 | A8011P | 8011 | EN AW-8011 | ~97,3–98,9 | ≤ 0,20 | Si 0,50–0,90; Fe 0,60–1,0 | Cu ≤ 0,10; Mn ≤ 0,20 |

Technical Specifications

| Alloy | Temper | Thickness (mm) | Width (mm) | Inner Diameter (mm) | Notes |

|---|---|---|---|---|---|

| 1050 | 1060 | 1100 | O | H12 | H14 | H16 | H18 | H22 | H24 | H32 | H111 | H112 | T6 | T651 | 0.1 – 10 | 10 – 2500 | 305 | 405 | 505 | Customized coil or sheet dimensions available |

| 3003 | 3004 | 3104 | 3105 | |||||

| 5005 | 5052 | 5083 | 5754 | 5182 | |||||

| 6061 | 6063 | 6083 | |||||

| 8011 | 8006 | 8079 | 3003 | 1235 | O | H22 | H24 | 0.006 – 0.2 | 20 – 1500 | 75 | 150 |

DULICO’s Commitment

At DULICO, every aluminum sheet or strip represents not only a product, but a commitment to quality, consistency, and long-term partnership.

- Products comply with international standards and are supplied with full inspection certificates.

- Reliable delivery, with complete support for logistics and import–export documentation.

- In-depth technical consultation, including alloy selection, temper designation, process compatibility, and application-specific optimization.

With strong expertise in non-ferrous metal processing and precision engineering, DULICO is committed to delivering efficient, cost-effective, and sustainable solutions for your production needs.

To receive a quotation and detailed consultation on products and technical specifications, please contact:

| Mr. Doan Thanh Tung (David) International Sales 📞+84 975 441 115 ✉️ tung.doan@dulico.vn | Mr. Nguyen Trong Duy (LEO) Director ✉️ duy.nguyen@dulico.vn |