COPPER BUSBARS

COPPER BUSBARS

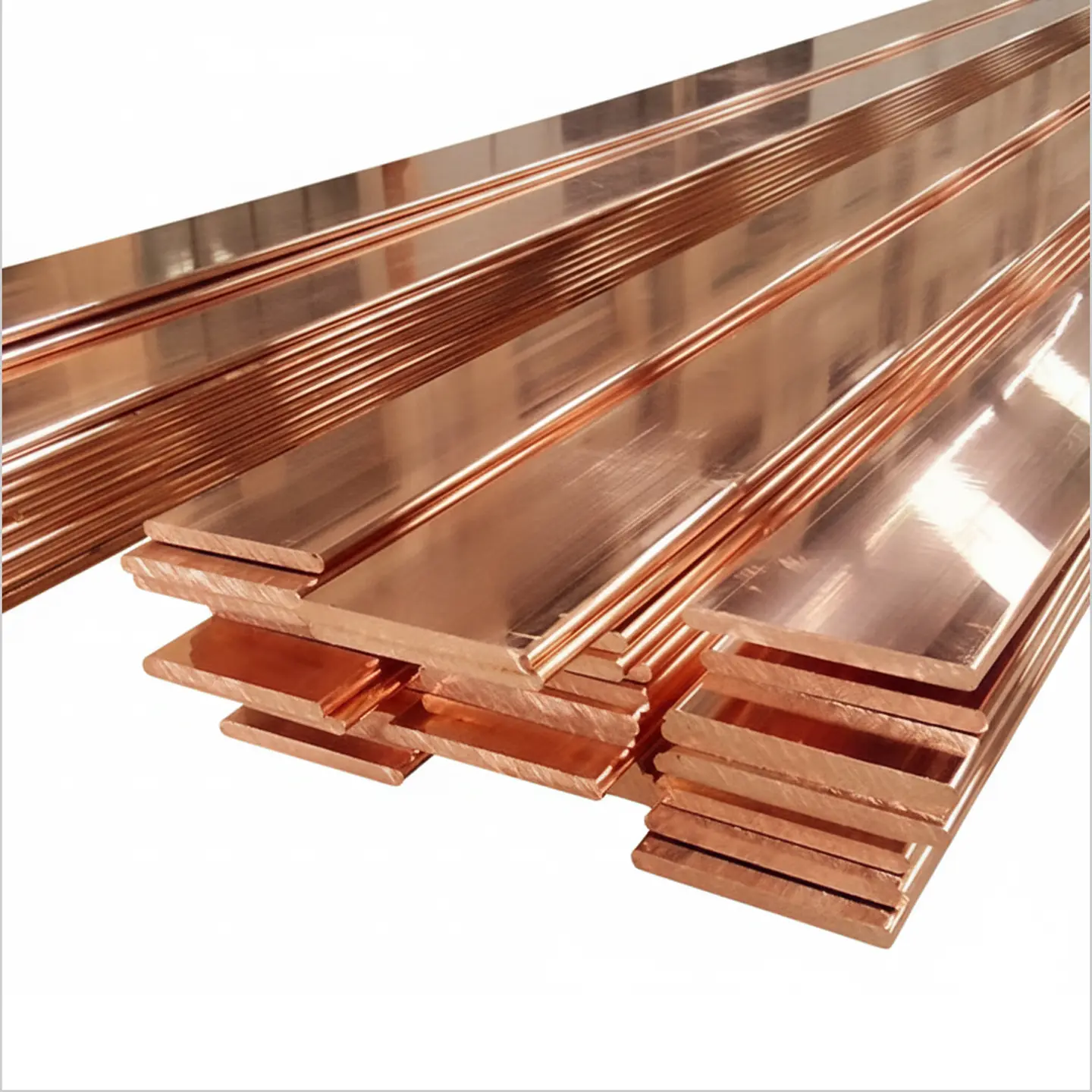

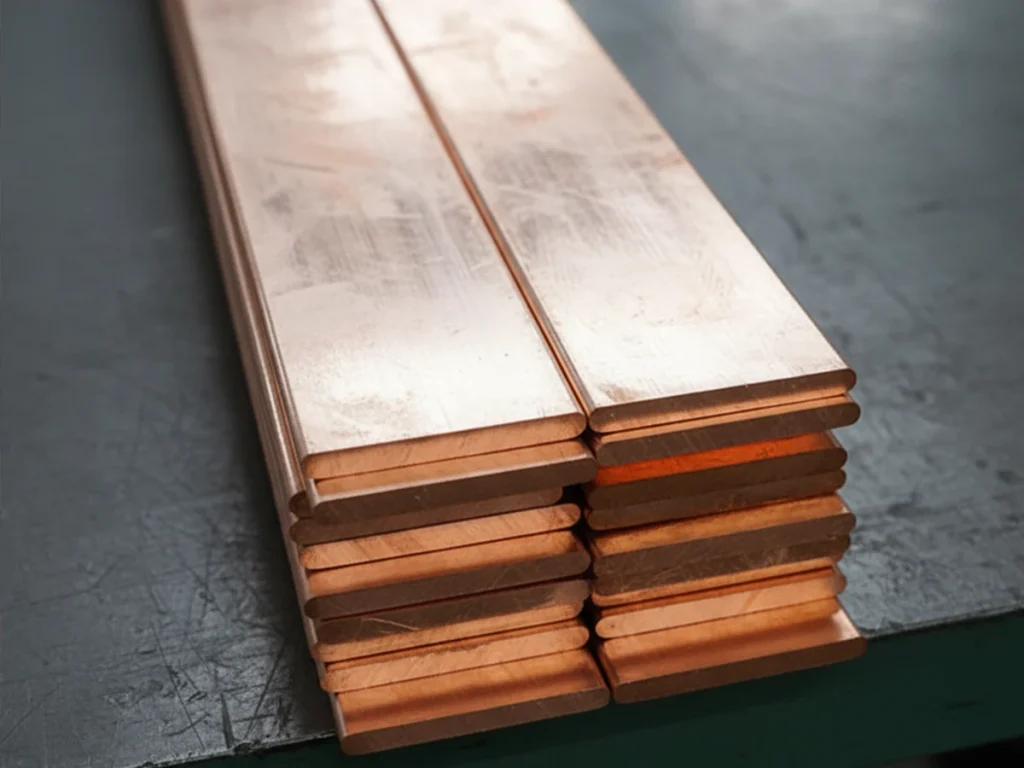

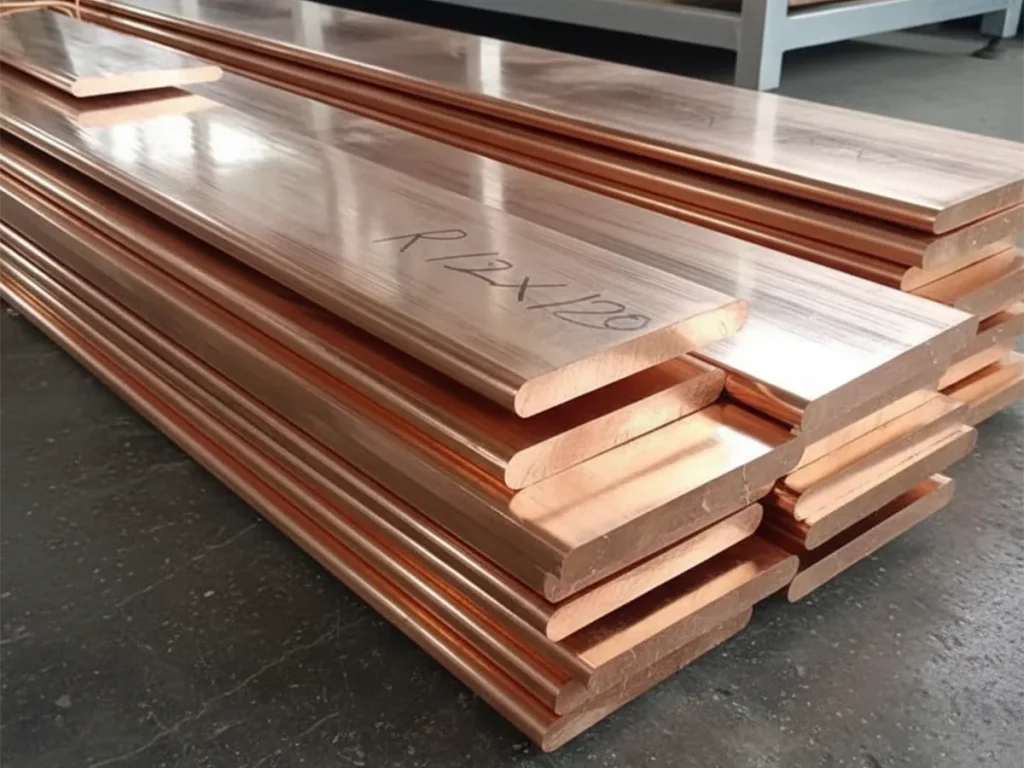

DULICO supplies high-quality copper busbars manufactured from electrolytic tough-pitch copper with a purity of Cu ≥ 99.90%, ensuring a bright, uniform surface, stable electrical conductivity, and excellent mechanical strength.

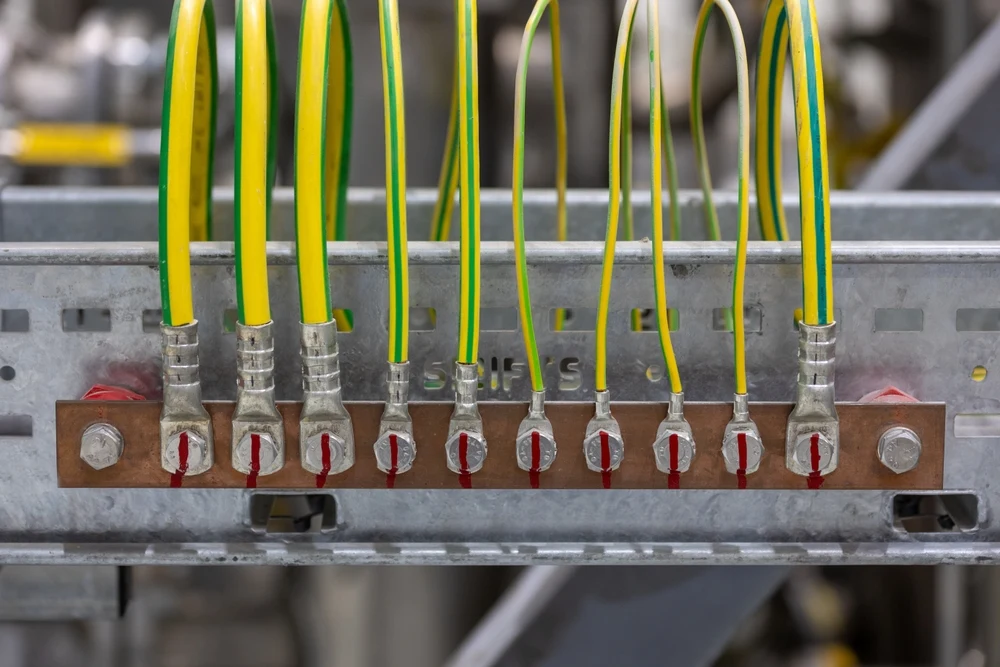

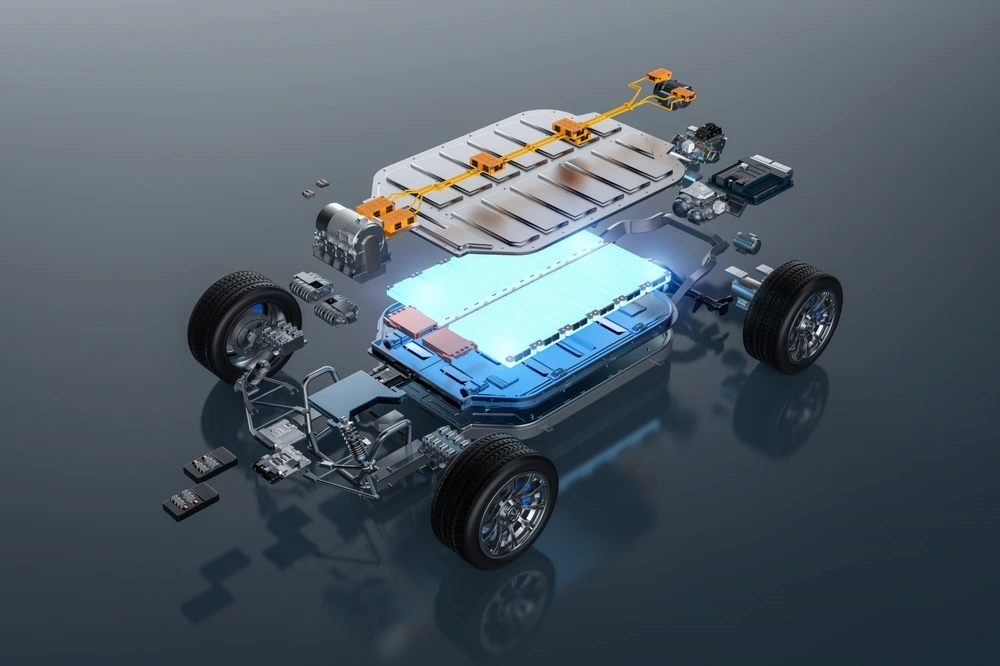

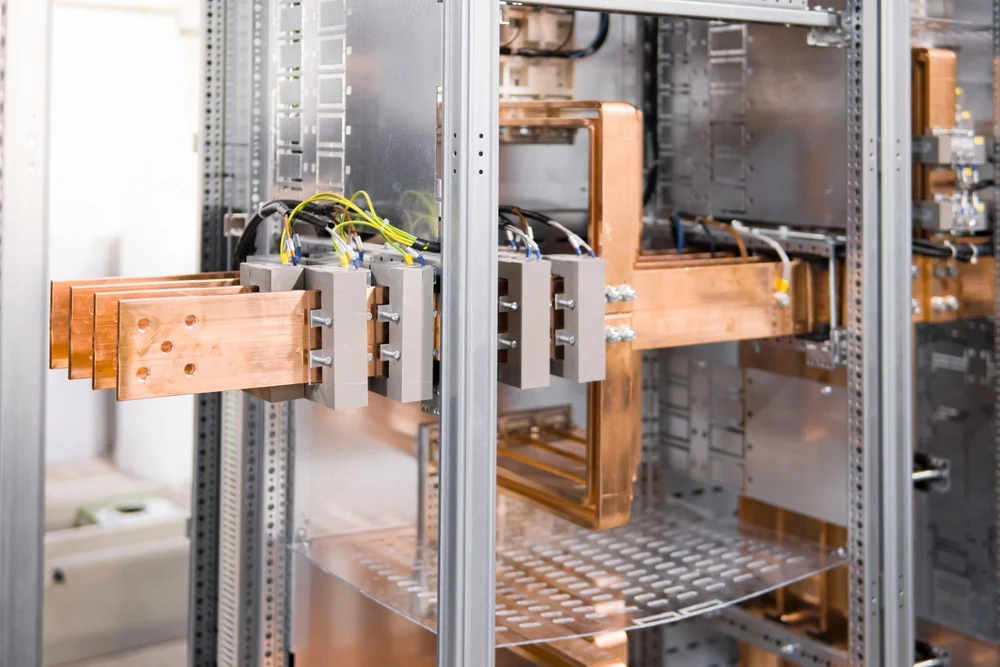

Our products comply with ISO 9001, ISO 14001, and ISO 45001, and are widely used in switchboards, substations, renewable-energy systems, and industrial electromechanical equipment.

Key Characteristics

Một số đặc tính quan trọng của đồng thanh cái có thể kể đến như:

- Superior electrical conductivity: Low resistivity enables high-current transmission with minimal energy loss.

- Thermal stability & heat dissipation: Ensures reliable performance under continuous high-load operation.

- High mechanical integrity: Resistant to bending, distortion, and mechanical stress during installation and operation.

- Corrosion & oxidation resistance: Surface can be tin-plated, nickel-plated, or silver-plated depending on application requirements.

- Wide dimensional range: Available in flat bars, rounded-edge bars, solid round bars, and thin coils to support diverse assembly and connection needs.

Applications

Copper busbars are widely used in sectors requiring high electrical performance and long-term reliability, including:

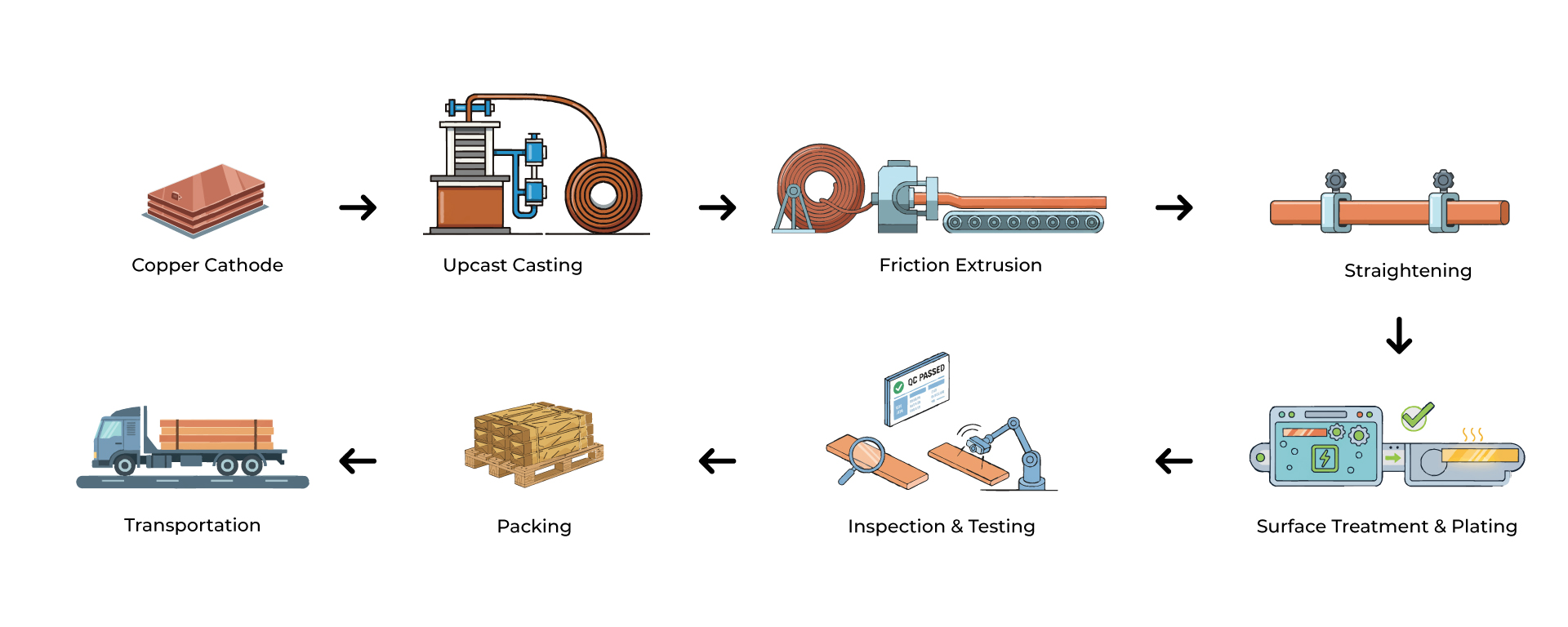

Manufacturing Process

DULICO copper busbars are produced through a fully integrated, closed-loop manufacturing process:

Raw material selection → Casting → Rolling / Friction extrusion → Straightening → Surface treatment → Quality inspection → Packaging

Each stage is tightly controlled to ensure dimensional accuracy, electrical performance, and surface perfection for every batch.

Product Specifications

DULICO offers a wide range of dimensions, from small flat bars to round-edge profiles, solid round sections, and custom-made designs based on drawings.

Typical Dimensions (Extract)

| No. | Rounded Edge (mm) | Special Dimensions (mm) | |

|---|---|---|---|

| 1 | 3×15 | 8×60 | 3.28×37.98 |

| 2 | 3×16 | 8×80 | 4.33×28 (1 groove) |

| 3 | 3×20 | 8×100 | 5.5×20 |

| 4 | 3×25 | 8×110 | 5.5×28 (2 groove) |

| 5 | 3×30 | 8×120 | 5.5×28 (3 groove) |

| 6 | 3×40 | 8×150 | 5.5×20 |

| 7 | 3×45 | 8×160 | 6~10x40V |

| 8 | 3×50 | 9.52×76.2 | 6/9×35 |

| 9 | 4×20 | 10×20 | 6.35×50.8 |

| 10 | 4×25 | 10×30 | 6.35×177.8 |

| 11 | 4×30 | 10×40 | 7×70.4 (1 groove) |

| 12 | 4×35 | 10×50 | 7.1×7.1 |

| 13 | 4×40 | 10×60 | 9.63×67.25 |

| 14 | 4×50 | 10×70 | 10×60 R4 |

| 15 | 4×60 | 10×75 | 10×125 R4 |

| 16 | 5×15 | 10×80 | 10.2×62.2 |

| 17 | 5×20 | 10×100 | 12×60 R2 |

| 18 | 5×25 | 10×110 | 12×65 R2 |

| 19 | 5×30 | 10×120 | 12×65 R5 |

| 20 | 5×40 | 10×125 | 12×65 R6 |

| 21 | 5×50 | 10×150 | 12×100 R5 |

| 22 | 5×60 | 10×180 | 19.7×114 |

| 23 | 5×80 | 12×100 | 19.8×117.5 |

| 24 | 5×100 | 12×150 | 19.9×115 |

| 25 | 6×12 | 12×160 | 58x70T |

| 26 | 6×20 | 20×120 | – |

| 27 | 6×25 | 20×150 | – |

| 28 | 6×30 | ||

| 29 | 6×40 | ||

| 30 | 6×50 | ||

| 31 | 6×60 | ||

| 32 | 6×80 | ||

| 33 | 6×100 | ||

| 34 | 6×110 | ||

| 35 | 6.35×76.2 | ||

| 36 | 6.35×101.6 | ||

| 37 | 6.35×127 | ||

| 38 | 8×20 | ||

| 39 | 8×25 | ||

| 40 | 8×30 | ||

| 41 | 8×40 | ||

| 42 | 8×50 | ||

DULICO Commitments

- International-standard products with complete CO and CQ documentation

- Reliable delivery schedules with full logistics and import-procedure support

- Technical consultation on alloy selection and dimensional optimization

- Sustainability orientation – DULICO copper busbars are 100% recyclable

With over 30 years of experience in non-ferrous metal processing, DULICO is a trusted manufacturing partner supplying copper busbars for power infrastructure, electronics, renewable-energy systems, and heavy-industry projects—delivering optimal quality, cost efficiency, and lead time.

To receive a quotation and detailed consultation on products and technical specifications, please contact:

| Mr. Doan Thanh Tung (David) International Sales 📞+84 975 441 115 ✉️ tung.doan@dulico.vn | Mr. Nguyen Trong Duy (LEO) Director ✉️ duy.nguyen@dulico.vn |