Stamping Parts

Precision Metal Stamping Services

At Dulico, we provide high-precision metal stamping services, ensuring top-notch quality in every product. With over 30 years of experience in precision engineering, a team of skilled technicians, and advanced technology, we are committed to delivering optimal solutions tailored to each customer’s needs.

Dulico supplies metal stamping components to various industries, including:

- Electrical & Electronics Industry: High-precision components for electrical applications.

- Automotive Industry: High-quality copper and copper alloy components for electrical and electronic systems in vehicles.

- Furniture & Construction:Key blanks, lock components, hinges, and structural parts.

- Water & Gas Industry:Valves, fittings, and handles.

TECHNICAL CAPABILITIES

Dulico owns a modern stamping press system with 30 presses, capable of processing materials with thicknesses from 0.1 to 5.0 mm and stamping forces from 500 kN to 3,000 kN. We not only work with copper and copper alloys produced by Dulico but also process materials like steel, stainless steel, aluminum, and other metals.

Stamping Presses at Dulico

| Specification | 10 – 60T Stamping Press | 80 – 260T Stamping Press |

|---|---|---|

| Pressing Force | 100 – 600 kN | 800 – 2.600 kN |

| Stroke per Minute (SPM) | Max 650 SPM | Max 140 SPM |

| Max Die Length | Max 1000 mm | Max 1500 mm |

| Material Standards | All standards | All standards |

| Max Material Width | Max 200 mm | Max 300 mm |

| Material Thickness Range | 0.1 – 2.5 mm | 0.1 – 4.5 mm |

| Dimensional Accuracy | Max 0.01 mm | Max 0.01 mm |

| Surface Treatment | Coating, plating, vibratory finishing, grinding, polishing, etc. | Coating, plating, vibratory finishing, grinding, polishing, etc. |

| Materials Processed | Copper, Steel, Stainless Steel, Aluminum | Copper, Steel, Stainless Steel, Aluminum |

Mold & Die Machining Equipment at Dulico

| Machine Name | FANUC ROBOCUT α-C400iC | ST4050F-M | KGS-618MNC | VMC-V855 | ST450 CNC |

|---|---|---|---|---|---|

| Type | CNC Wire Cut EDM (Copper Wire) | CNC Wire Cut EDM (Molybdenum Wire) | Surface Grinder | CNC Milling Machine | CNC Hole Drilling Machine |

| Brand | Japan | China | Taiwan | China | China |

| Travel X/Y/Z (mm) | 400 x 300 x 255 | 450 x 500 x 250 | 460 x 150 x 350 | 800 x 540 x 540 | 350 x 450 x400 |

| Worktable Size (mm) | 600 x 400 | 520 x 800 | 460 x 150 | 1000 x 550 | 470 x710 |

| Accuracy (mm) | ±0.001 | ±0.008 | ±0.001 | ±0.005 | ±0.02 |

| Spindle Speed (RPM) | – | – | – | 12.000 | – |

| Max Workpiece Load (kg) | 500 | 600 | 120 | 500 | 300 |

PRODUCT QUALITY

At Dulico, quality is our top priority. We implement strict quality control processes based on TPM and ISO 9001:2015 standards to ensure all products meet stringent technical requirements.

To achieve accurate and consistent quality control, Dulico is equipped with advanced QC machinery:

| Equipment | Brand |

|---|---|

| Salt Spray Test Machine | China |

| 2D Measuring Machine | Taiwan |

| Digital Height Gauge – Mitutoyo | Japan |

| Digital Caliper – Mitutoyo | Japan |

| Surface Roughness Tester – Mitutoyo | Japan |

| Digital Micrometer – Mitutoyo | Japan |

| Hardness Tester | Japan |

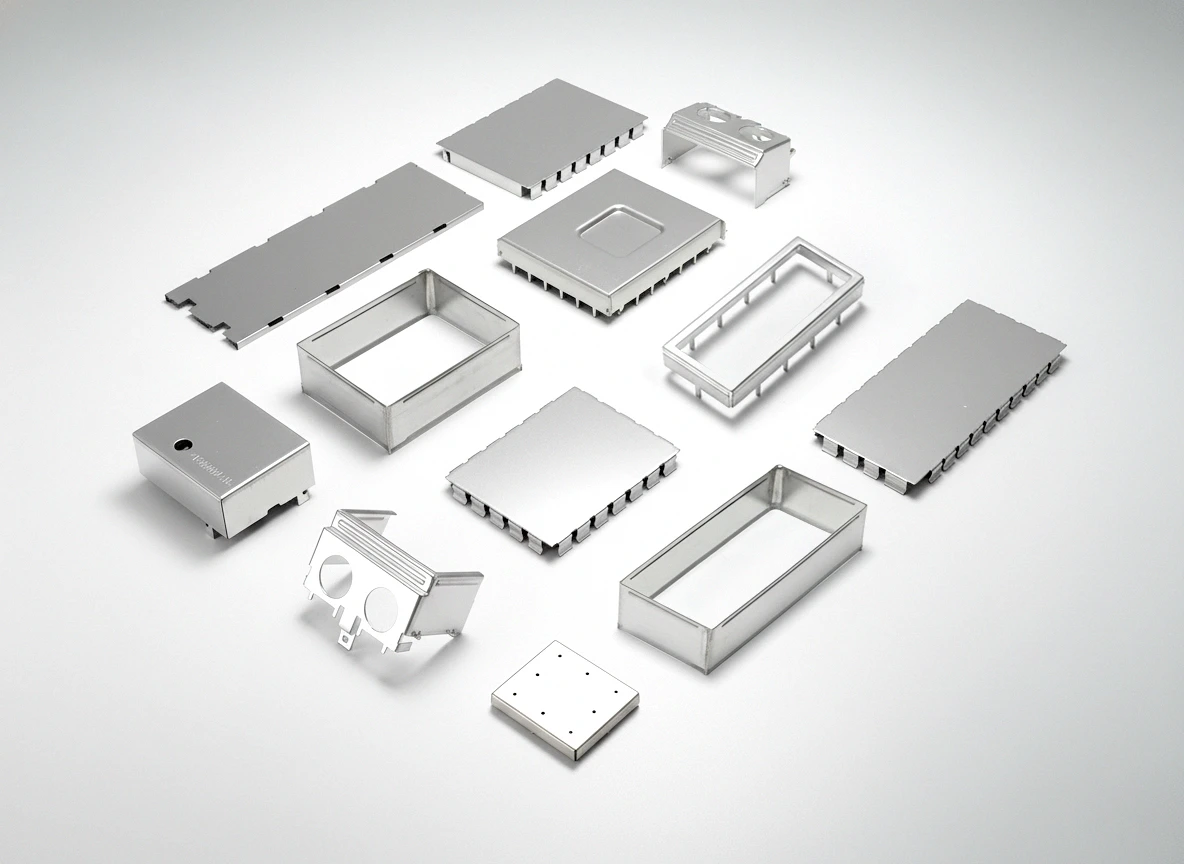

APPLICATIONS OF METAL STAMPING

Our metal stamping products are widely used across multiple industries, including:

To receive a quotation and detailed consultation on products and technical specifications, please contact:

| Mr. Doan Thanh Tung (David) International Sales 📞+84 975 441 115 ✉️ tung.doan@dulico.vn | Mr. Nguyen Trong Duy (LEO) Director ✉️ duy.nguyen@dulico.vn |

Stamped product

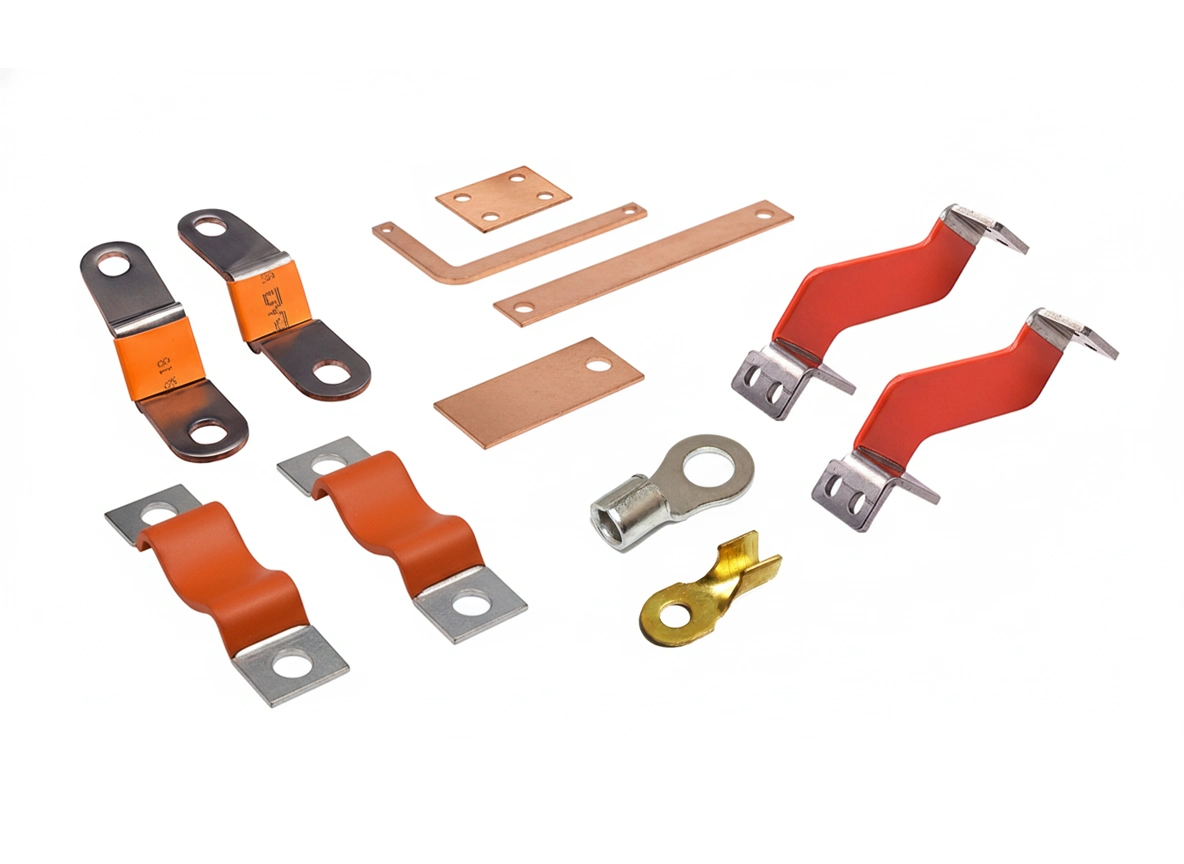

Busbars & Power Conduction Components

Busbars and power conduction components are large-format copper parts used to conduct and distribute electrical current inside electrical panels, inverters, UPS units, and industrial systems.

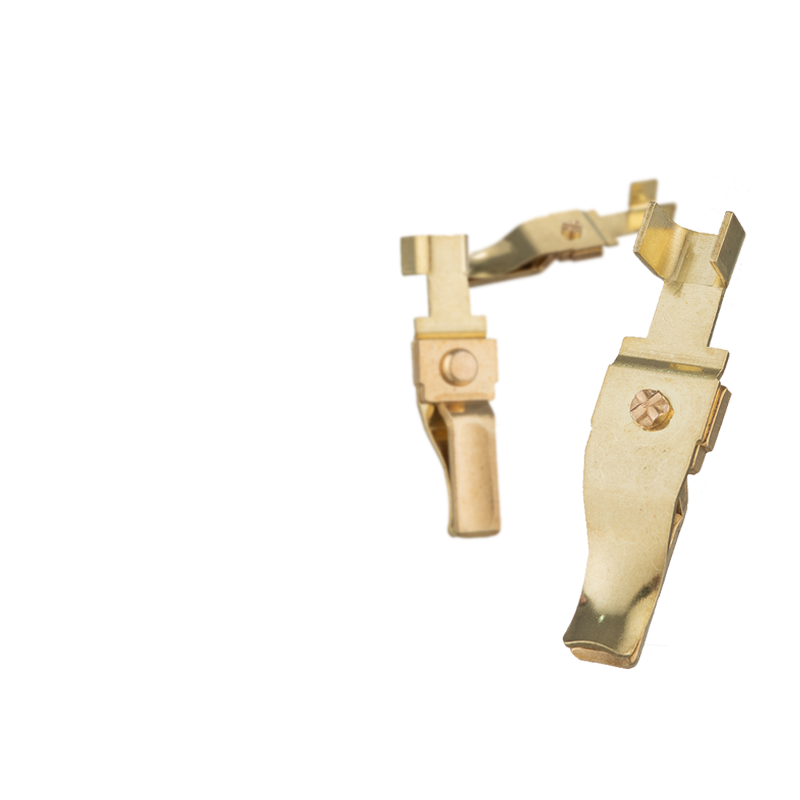

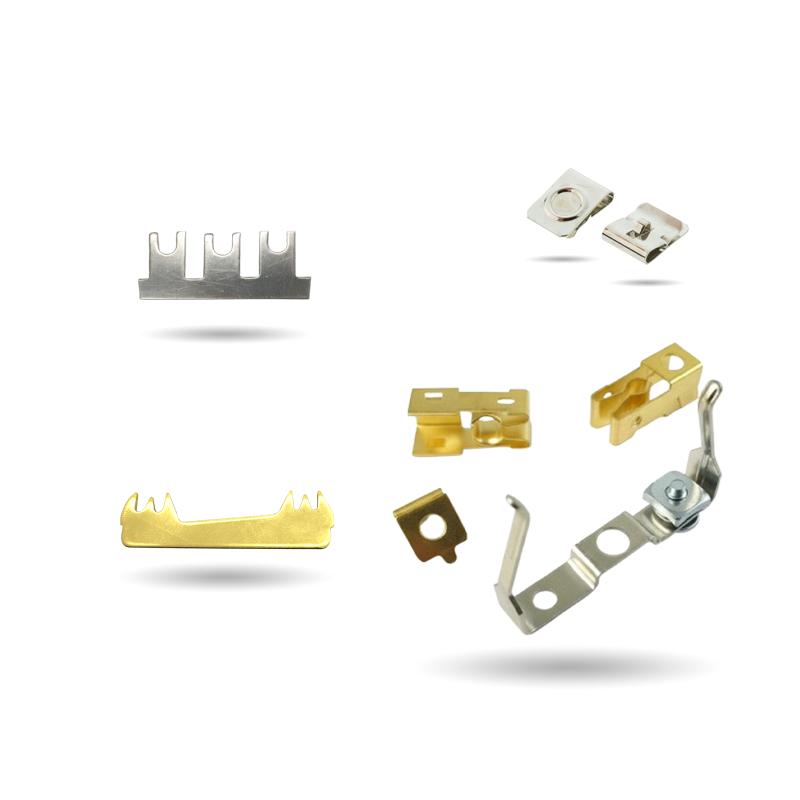

Contact Components & Wire-Locking Parts

Contact components and wire-locking parts are manufactured strictly to OEM drawings for both residential and industrial electrical devices.Production complies with ISO 9001:2015 quality standards.

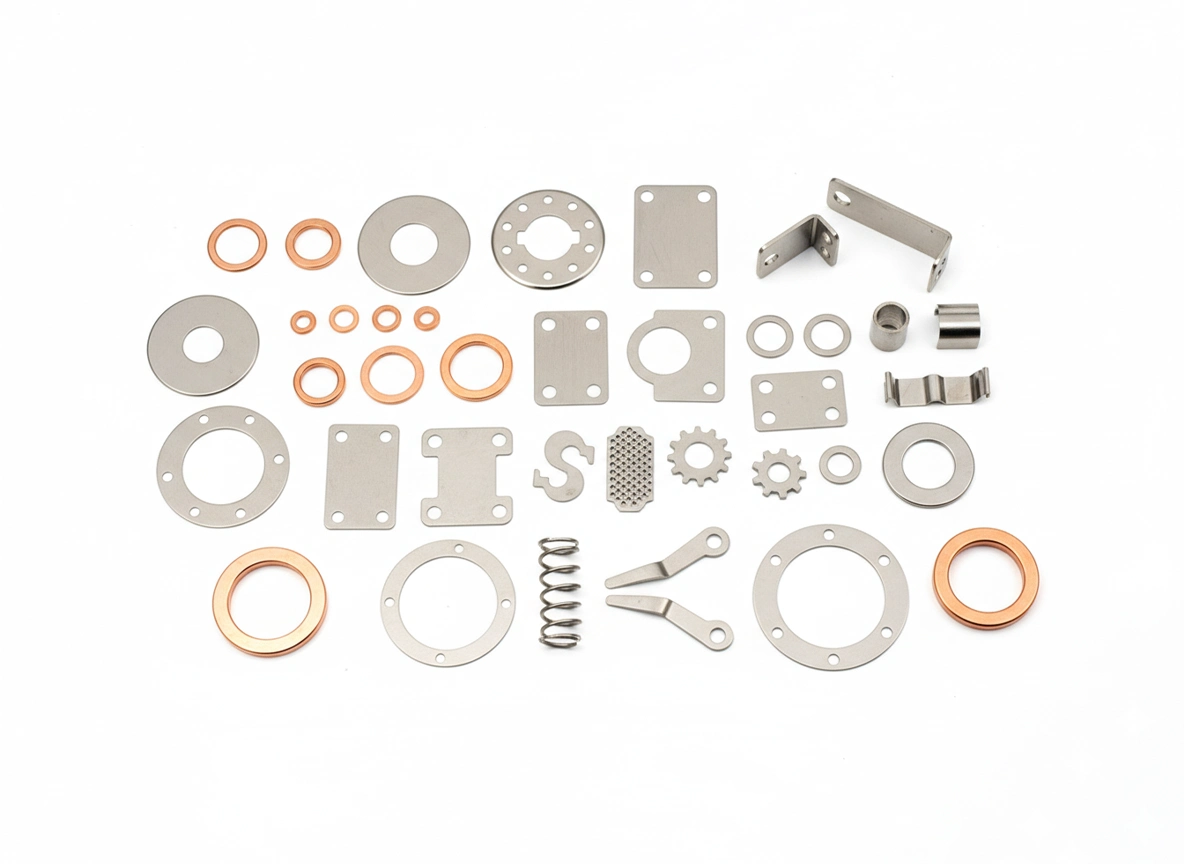

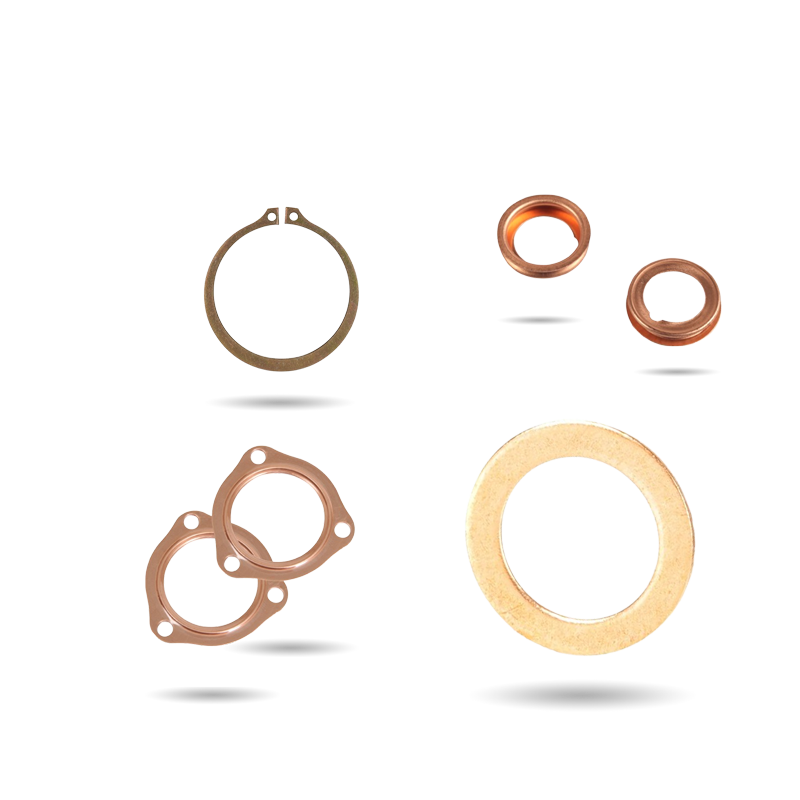

Washers – Spacers – Precision Shims

Dulico manufactures a full range of technical washers—from steel and brass flat washers to custom spacers, precision shims, and metal gaskets—strictly according to OEM drawings, ensuring dimensional accuracy and reliable functional performance.

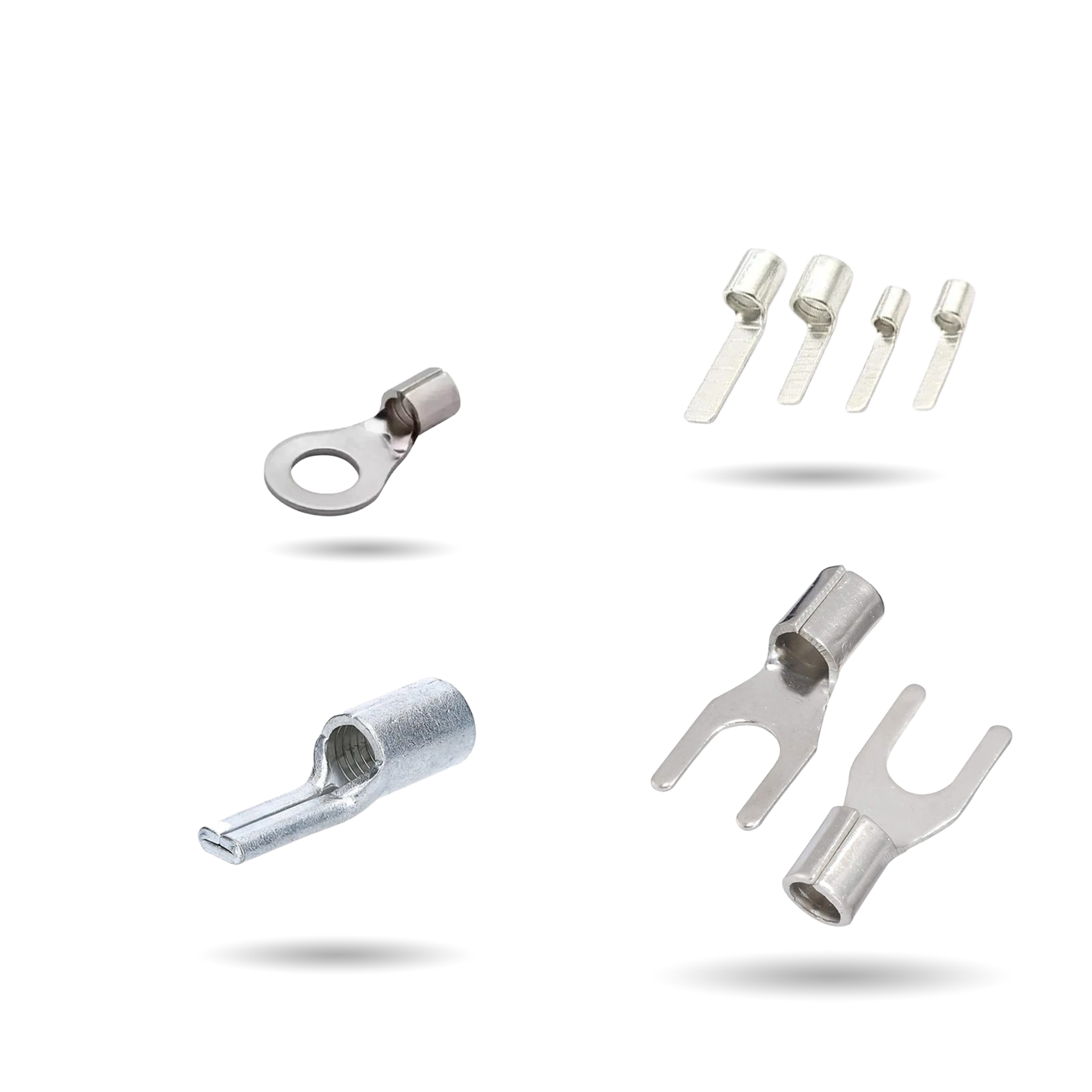

Copper Lugs – Crimp Terminals

Copper and brass lugs, crimp terminals, and connector ends produced by stamping, annealing, and tin/nickel plating at Dulico—suitable for electrical panels, inverters, power cables, and industrial equipment.

Clamps, Holders & Copper Fastening Components

U-clamps, thin busbar clamps, grounding clamps, and other copper/brass fastening parts are manufactured at Dulico using precision stamping, bending, and plating processes.

Progressive Die Stamping 02

Material: Brass C2600, C2680... - Manufacturing Technology: Deep Draw Stamping