Tinned Copper Wire

Tinned Copper Wire

DULICO offers high-quality tinned copper wire, manufactured from refined copper (Cu ≥ 99.95%) and electroplated with a bright, uniform tin layer. The tin coating enhances oxidation resistance, improves solderability, maintains stable conductivity, and extends the lifespan of the wire in humid, vibrating, or high-temperature environments.

Thanks to these technical advantages, tinned copper wire is widely used in electronics, automation, industrial systems, and environments with high moisture or mechanical vibration.

Technical Features

- Oxidation and corrosion resistance: Tin layer protects the copper core.

- Stable electrical conductivity: Performs well in high-vibration, humid, or temperature-variable conditions.

- Uniform dimensions: Ideal for automated processing (crimping, terminal applications).

- Excellent solderability: Tin coating ensures even solder adhesion for PCB and board-level connections.

- Flexible structural options: Available in solid or stranded wire configurations.

Certifications & Quality Standards

Management systems: ISO 9001:2015, ISO 14001:2015, QC080000:2017

Environmental and chemical safety: RoHS 2.0, REACH, California Proposition 65

Product certifications (based on wire type): UL 1007, UL 1015, UL 1571, UL 1589

Machinery and Equipment

DULICO supports product quality with modern machinery imported from Japan, Germany, Italy, and China. Quality control is conducted rigorously throughout production: IQC, LINE QC, OQC, and 100% OQC before warehousing.

Equipment List

| Equipment | Quantity |

|---|---|

| Wire drawing machines | 5 |

| Copper annealing furnaces | 2 |

| Tin-plating machines | 5 |

| Wire braiding machines | 3 |

| Wire coiling & insulation units | 2 |

| QC Testing Equipment | |

| Micrometers | 20 |

| Resistance meters | 5 |

| Elongation testers | 1 |

| Surface defect scanners | 1 |

| Precision scales | 10 |

Applications of Tinned Copper Wire

Thanks to its superior properties, tinned copper wire is used across various sectors:

Applications of Tinned Copper Wire

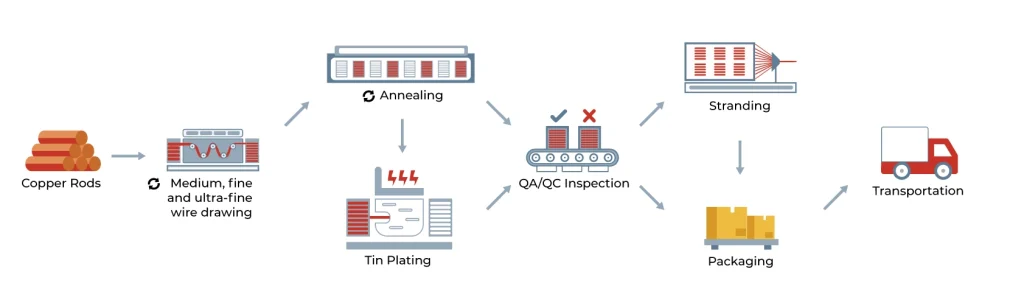

Production Process

The manufacturing of tinned copper wire is strictly controlled from raw material selection through to finished product quality assurance.

Technical Specifications

DULICO supplies tinned copper wire in a wide range of diameters and technical configurations:

- Conductivity: ~100% IACS

- Outer diameter (OD): 0.05 mm – 2.6 mm

- OD tolerance: ±0.003–0.026 mm

- Resistivity: 3.249 Ω/km (2.6 mm) to 8.786 Ω/km (0.05 mm)

- Elongation: 5% (ultrafine wires) to 25% (larger gauges)

Detailed datasheets or technical consultation:

Technical Specification Table – Solid Copper Wire

| OD (mm) | Tolerance (±mm) | OD Range (mm) | Conductivity (@20°C %IACS) | Resistance (@20°C Ω/km) | Min. Elongation BC (%) | Min. Elongation TC (%) |

|---|---|---|---|---|---|---|

| 0.05 | 0,003 | 0,047–0,053 | 100 | 8786,000 | 7 | 5 |

| 0.06 | 0,003 | 0,057–0,063 | 100 | 6101,200 | 7 | 5 |

| 0.08 | 0,003 | 0,077–0,083 | 100 | 3432,000 | 12 | 10 |

| 0.09 | 0,003 | 0,087–0,093 | 100 | 2711,700 | 12 | 10 |

| 0.10 | 0,003 | 0,097–0,103 | 100 | 2196,500 | 12 | 10 |

| 0.114 | 0,003 | 0,111–0,117 | 100 | 1690,100 | 12 | 10 |

| 0.12 | 0,003 | 0,117–0,123 | 100 | 1520,500 | 12 | 12 |

| 0.127 | 0,003 | 0,124–0,130 | 100 | 1361,800 | 12 | 12 |

| 0.14 | 0,003 | 0,137–0,143 | 100 | 1120,650 | 12 | 12 |

| 0.15 | 0,003 | 0,147–0,153 | 100 | 976,190 | 15 | 12 |

| 0.155 | 0,003 | 0,152–0,158 | 100 | 914,220 | 15 | 12 |

| 0.16 | 0,003 | 0,157–0,163 | 100 | 858,000 | 15 | 12 |

| 0.175 | 0,003 | 0,172–0,178 | 100 | 717,210 | 15 | 15 |

| 0.18 | 0,003 | 0,177–0,183 | 100 | 677,920 | 15 | 15 |

| 0.19 | 0,003 | 0,187–0,193 | 100 | 608,450 | 15 | 15 |

| 0.2 | 0,003 | 0,197–0,203 | 100 | 549,120 | 15 | 15 |

| 0.203 | 0,003 | 0,200–0,206 | 100 | 533,000 | 15 | 15 |

| 0.226 | 0,003 | 0,223–0,229 | 100 | 430,050 | 15 | 15 |

| 0.23 | 0,003 | 0,227–0,233 | 100 | 415,220 | 15 | 15 |

| 0.24 | 0,003 | 0,237–0,243 | 100 | 381,330 | 15 | 15 |

| 0.245 | 0,003 | 0,242–0,248 | 100 | 365,920 | 15 | 15 |

| 0.247 | 0,003 | 0,244–0,250 | 100 | 360,030 | 15 | 15 |

| 0.25 | 0,003 | 0,247–0,253 | 100 | 351,430 | 15 | 15 |

| 0.254 | 0,003 | 0,251–0,257 | 100 | 340,450 | 15 | 15 |

| 0.26 | 0,003 | 0,257–0,263 | 100 | 324,920 | 20 | 15 |

| 0.29 | 0,003 | 0,287–0,293 | 100 | 261,180 | 20 | 15 |

| 0.32 | 0,003 | 0,317–0,323 | 100 | 214,500 | 20 | 15 |

| 0.361 | 0,004 | 0,357–0,365 | 100 | 168,540 | 20 | 15 |

| 0.404 | 0,004 | 0,400–0,408 | 100 | 134,570 | 20 | 15 |

| 0.455 | 0,005 | 0,450–0,460 | 100 | 110,920 | 20 | 15 |

| 0.511 | 0,005 | 0,506–0,516 | 100 | 84,120 | 20 | 20 |

| 0.574 | 0,005 | 0,568–0,580 | 100 | 66,860 | 25 | 20 |

| 0.635 | 0,005 | 0,630–0,640 | 100 | 54,470 | 25 | 20 |

| 0.643 | 0,006 | 0,637–0,649 | 100 | 52,950 | 25 | 20 |

| 0.717 | 0,006 | 0,717–0,731 | 100 | 41,903 | 25 | 20 |

| 0.813 | 0,007 | 0,805–0,821 | 100 | 33,231 | 25 | 20 |

| 0.912 | 0,009 | 0,903–0,921 | 100 | 26,408 | 25 | 20 |

| 1.02 | 0,01 | 1,01–1,03 | 100 | 21,110 | 25 | 20 |

| 1.15 | 0,012 | 1,138–1,162 | 100 | 16,609 | 25 | 20 |

| 1.29 | 0,013 | 1,277–1,303 | 100 | 13,200 | 25 | 20 |

| 1.63 | 0,016 | 1,614–1,646 | 100 | 8,267 | 25 | 20 |

| 2.05 | 0,021 | 2,029–2,071 | 100 | 5,226 | 25 | 20 |

| 2.6 | 0,026 | 2,574–2,626 | 100 | 3,249 | 25 | 20 |

Technical Specification Table – Tinned Copper Wire

| Nominal OD (mm | OD Tolerance (±mm) | OD Range (mm) | Outer Diameter (mm) | Outer OD Tolerance (±mm) | Conductivity (@20°C %IACS) | Electrical Resistance (@20°C Ω/km) | Lay Direction | Lay Length (mm) | Min. Elongation BC | Min. Elongation TC |

|---|---|---|---|---|---|---|---|---|---|---|

| 7/0.0787 | 0.003 | 0.0757-0.0817 | 0.24 | 0.03 | 100 | 506.6 | S | 2.5 – 4.5 | 12 | 10 |

| 7/0.08 | 0.003 | 0.077-0.083 | 0.24 | 0.03 | 100 | 190.3 | S | 2.5 – 4.5 | 12 | 10 |

| 7/0.10 | 0.003 | 0.097-0.103 | 0.3 | 0.03 | 100 | 313.8 | S | 7 – 9 | 15 | 10 |

| 7/0.120 | 0.003 | 0.117-0.123 | 0.37 | 0.03 | 100 | 217.95 | S | 8 – 10 | 15 | 12 |

| 7/0.127 | 0.003 | 0.124-0.130 | 388 | 0.05 | 100 | 194.54 | S | 7 – 9 | 15 | 12 |

| 7/0.153 | 0.003 | 0.150-0.156 | 467 | 0.05 | 100 | 134.1 | S | 8 – 10 | 15 | 12 |

| 7/0.156 | 0.003 | 0.153-0.159 | 476 | 0.05 | 100 | 128.95 | S | 11 – 13 | 15 | 12 |

| 7/0.158 | 0.003 | 0.155-0.161 | 482 | 0.05 | 100 | 125.7 | S | 14 – 16 | 15 | 12 |

| 7/0.160 | 0.003 | 0.157-0.163 | 488 | 0.05 | 100 | 122.57 | S | 14 – 16 | 18 | 15 |

| 7/0.175 | 0.003 | 0.172-0.178 | 534 | 0.05 | 100 | 102.5 | S | 13 – 15 | 18 | 15 |

| 7/0.193 | 0.003 | 0.190-0.196 | 589 | 0.05 | 100 | 84.25 | S | 12 – 14 | 18 | 15 |

| 7/0.195 | 0.003 | 0.192-0.198 | 595 | 0.05 | 100 | 82.55 | S | 14 – 16 | 18 | 15 |

| 8/0.176 | 0.003 | 0.173-0.179 | 575 | 0.05 | 100 | 88.63 | S | 40 – 45 | 18 | 15 |

| 11/0.08 | 0.003 | 0.077-0.083 | 306 | 0.03 | 100 | 312.09 | S | 7 – 9 | 12 | 10 |

| 11/0.10 | 0.003 | 0.097-0.103 | 383 | 0.03 | 100 | 199.7 | S | 7 – 9 | 15 | 12 |

| 11/0.160 | 0.003 | 0.157-0.163 | 612 | 0.05 | 100 | 78.02 | S | 12 – 16 | 18 | 15 |

| 12/0.176 | 0.003 | 0.173-0.179 | 704 | 0.05 | 100 | 59.1 | S | 16 – 18 | 18 | 15 |

| 15/0.10 | 0.003 | 0.097-0.103 | 447 | 0.05 | 100 | 146.5 | S | 7 – 9 | 15 | 12 |

| 16/0.08 | 0.003 | 0.077-0.083 | 0.37 | 0.03 | 100 | 214.51 | S | 4 – 7 | 12 | 10 |

| 16/0.175 | 0.003 | 0.172-0.178 | 808 | 0.05 | 100 | 44.82 | S | 18 – 20 | 18 | 15 |

| 16/0.18 | 0.003 | 0.177-0.183 | 0.83 | 0.05 | 100 | 42.38 | S | 19 – 21 | 18 | 15 |

| 16/0.20 | 0.003 | 0.197-0.203 | 924 | 0.05 | 100 | 34.32 | S | 22 – 25 | 18 | 15 |

| 16/0.193 | 0.003 | 0.190-0.196 | 0.9 | 0.05 | 100 | 36.86 | S | 28 – 32 | 18 | 15 |

| 17/0.160 | 0.003 | 0.157-0.163 | 762 | 0.05 | 100 | 50.48 | S | 20 – 22 | 18 | 15 |

| 19/0.054 | 0.003 | 0.051-0.057 | 0.27 | 0.03 | 100 | 396.5 | S | 6 – 7 | 12 | 8 |

| 19/0.08 | 0.003 | 0.077-0.083 | 403 | 0.03 | 100 | 180.65 | S | 3.7 – 4.7 | 12 | 10 |

| 20/0.175 | 0.003 | 0.172-0.178 | 904 | 0.05 | 100 | 35.86 | S | 24 – 26 | 18 | 15 |

| 20/0.176 | 0.003 | 0.173-0.179 | 909 | 0.05 | 100 | 35.46 | S | 25 – 26 | 18 | 15 |

| 21/0.10 | 0.003 | 0.097-0.103 | 0.53 | 0.05 | 100 | 104.6 | S | 11 – 13 | 15 | 10 |

| 21/0.160 | 0.003 | 0.157-0.163 | 846 | 0.05 | 100 | 40.87 | S | 20 – 25 | 18 | 15 |

| 24/0.194 | 0.003 | 0.191-0.197 | 1.097 | 0.05 | 100 | 24.32 | S | 30 – 33 | 18 | 15 |

| 25/0.160 | 0.003 | 0.157-0.163 | 924 | 0.05 | 100 | 34.33 | S | 25 – 29 | 18 | 15 |

| 26/0.08 | 0.003 | 0.077-0.083 | 471 | 0.03 | 100 | 132.03 | S | 2.5 – 3.5 | 12 | 8 |

| 27/0.175 | 0.003 | 0.172-0.178 | 01.05 | 0.05 | 100 | 26.57 | S | 21 – 23 | 18 | 15 |

| 30/0.08 | 0.003 | 0.077-0.083 | 506 | 0.05 | 100 | 114.42 | S | 4.5 – 7.5 | 12 | 8 |

| 30/0.10 | 0.003 | 0.097-0.103 | 632 | 0.05 | 100 | 73.25 | S | 7 – 9 | 15 | 12 |

| 30/0.175 | 0.003 | 0.172-0.178 | 1.107 | 0.05 | 100 | 23.91 | S | 21 – 23 | 18 | 15 |

| 30/0.176 | 0.003 | 0.173-0.179 | 1.113 | 0.05 | 100 | 23.64 | S | 22 – 25 | 18 | 15 |

| 30/0.240 | 0.003 | 0.237-0.243 | 1.518 | 0.05 | 100 | 12.71 | S | 28 – 32 | 18 | 15 |

| 30/0.243 | 0.003 | 0.240-0.246 | 1.537 | 0.05 | 100 | 12.4 | S | 48 – 56 | 18 | 15 |

| 30/0.247 | 0.003 | 0.243-0.250 | 1.562 | 0.05 | 100 | 12 | S | 35 – 40 | 18 | 15 |

| 32/0.198 | 0.003 | 0.195-0.201 | 1.293 | 0.05 | 100 | 17.51 | S | 30 – 33 | 18 | 15 |

| 37/0.05 | 0.003 | 0.047-0.053 | 351 | 0.03 | 100 | 237.5 | S | 4 – 6 | 12 | 8 |

| 37/0.057 | 0.003 | 0.054-0.06 | 0.4 | 0.03 | 100 | 182.75 | S | 6.5 – 7.5 | 12 | 8 |

| 37/0.08 | 0.003 | 0.077-0.083 | 421 | 0.03 | 100 | 92.8 | S | 7 – 9 | 12 | 8 |

| 41/0.08 | 0.003 | 0.077-0.083 | 591 | 0.05 | 100 | 83.72 | S | 5 – 6 | 12 | 10 |

| 41/0.150 | 0.003 | 0.147-0.153 | 1.109 | 0.05 | 100 | 23.81 | S | 40 – 48 | 15 | 12 |

| 41/0.160 | 0.003 | 0.157-0.163 | 1.18 | 0.05 | 100 | 20.93 | S | 32 – 34 | 18 | 15 |

| 50/0.240 | 0.003 | 0.237-0.243 | 1.95 | 0.05 | 100 | 7.63 | S | 39 – 42 | 18 | 15 |

| 50/0.243 | 0.003 | 0.240-0.246 | 1.984 | 0.05 | 100 | 7.44 | S | 61 – 71 | 18 | 15 |

| 50/0.247 | 0.003 | 0.243-0.250 | 2.017 | 0.05 | 100 | 7.202 | S | 40 – 45 | 18 | 15 |

| 65/0.08 | 0.003 | 0.077-0.083 | 745 | 0.05 | 100 | 52.82 | S | 12.5 – 15.5 | 13 | 10 |

| 65/0.150 | 0.003 | 0.147-0.153 | 1.4 | 0.05 | 100 | 15.02 | S | 60 – 62 | 20 | 17 |

Download: profile-copper-wire.pdf

Frequently Asked Questions (FAQ)

Where can tinned copper wire be used?

Tinned copper wire is suitable for use in control circuits, jumper wires, signal transmission, crimped terminal connections, sensors, and automated control systems.

Can I place custom orders?

Absolutely. We can accommodate specific requirements in terms of diameter (AWG/mm), hardness, wire structure, tin coating, spool length, and packaging specifications.

What is the difference between tinned copper wire and bare copper wire?

Tinned copper wire features a protective tin coating that enhances corrosion resistance and durability in humid or industrial environments. In contrast, bare copper wire is more prone to tarnishing and may lose contact stability over time.

To receive a quotation and detailed consultation on products and technical specifications, please contact:

| Mr. Doan Thanh Tung (David) International Sales 📞+84 975 441 115 ✉️ tung.doan@dulico.vn | Mr. Nguyen Trong Duy (LEO) Director ✉️ duy.nguyen@dulico.vn |