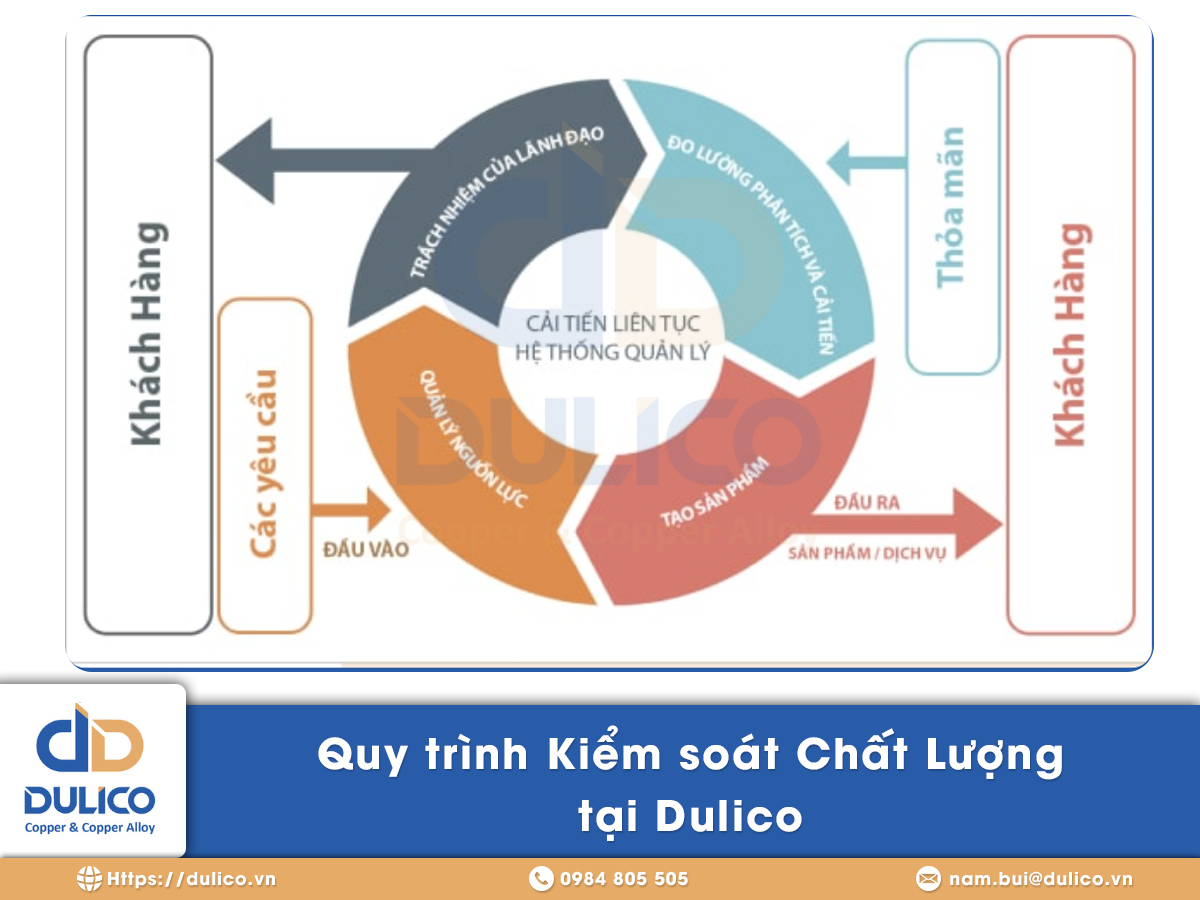

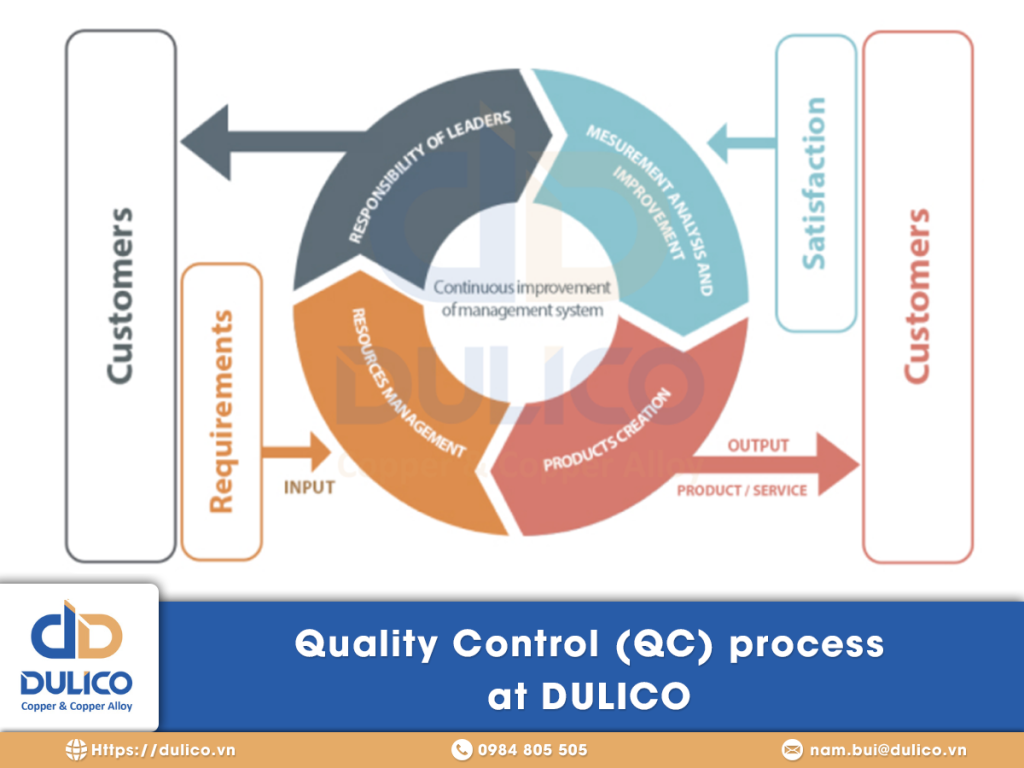

Dulico always puts product quality first. To ensure that every product leaving the factory meets the highest standards, we have built a strict quality control (QC) process, including the following stages:

1. Control of Incoming Materials

- Origin inspection: All input materials are carefully checked for origin, provenance, and quality certification.

- Component analysis: Raw materials are analyzed to ensure compliance with the established technical standards.

- Appearance inspection: Check the size, shape, color, and surface of raw materials.

2. Production Process Control

- Using modern machinery: Dulico invests in modern machinery and production equipment, ensuring high precision in each stage.

- Comply with the process: All production stages are carried out in accordance with approved technological processes.

- Periodic inspection: Periodic inspection of technical parameters during the production process.

3. Finished Product Control

- Appearance inspection: Check the size, shape, color, surface of the finished product.

- Physical inspection: Check the physical properties such as hardness, strength, toughness.

- Chemical inspection: Analyze the chemical composition to ensure the product meets the standards.

- Dimensional inspection: Check the dimensions of the product to ensure it meets the technical requirements.

4. Packaging and Shipping Control

- Careful packaging: The product is carefully packaged to avoid damage during transportation.

- Pre-shipment re-inspection: Check again before delivery to ensure the product is perfect.

5. Customer feedback

- Collect information: Collect feedback from customers about the product quality.

- Analyze and improve: Analyze this information to find out the points that need improvement and come up with suitable solutions.

Quality standards

Dulico always complies with international quality standards such as ISO 9001:2015 to ensure product and service quality.

Dulico’s commitment:

- Quality is the top priority: We always put product quality first, constantly improving to bring the best products to customers.

- Customer is the center: We always listen to customers’ opinions and constantly improve products to meet customers’ needs.

- Professional staff: We have a team of experienced and highly qualified staff.

With a strict quality control process and a commitment to continuous improvement, Dulico is confident in bringing customers high quality products, meeting all customer requirements.

Precision Metal Stamping at DULICO – Accuracy in Every Detail

Precision Metal Stamping at DULICO – Accuracy in Every DetailLooking for a reliable partner in precision metal stamping with stability and flexibility? DULICO offers high-precision stamping services that meet...

DULICO – Corporate Introduction Video May 19, 2025

DULICO – Corporate Introduction Video May 19, 2025With nearly 35 years of development, DULICO is a pioneering enterprise in Vietnam in the field of copper strip casting...

Dulico – OEM Manufacturer of Copper Components for IPC Connectors

Dulico – OEM Manufacturer of Copper Components for IPC ConnectorsIn the manufacturing of insulated piercing connectors (IPCs), mechanical and electrical component producers face several challenges: consistent quality, cost-efficiency, and...

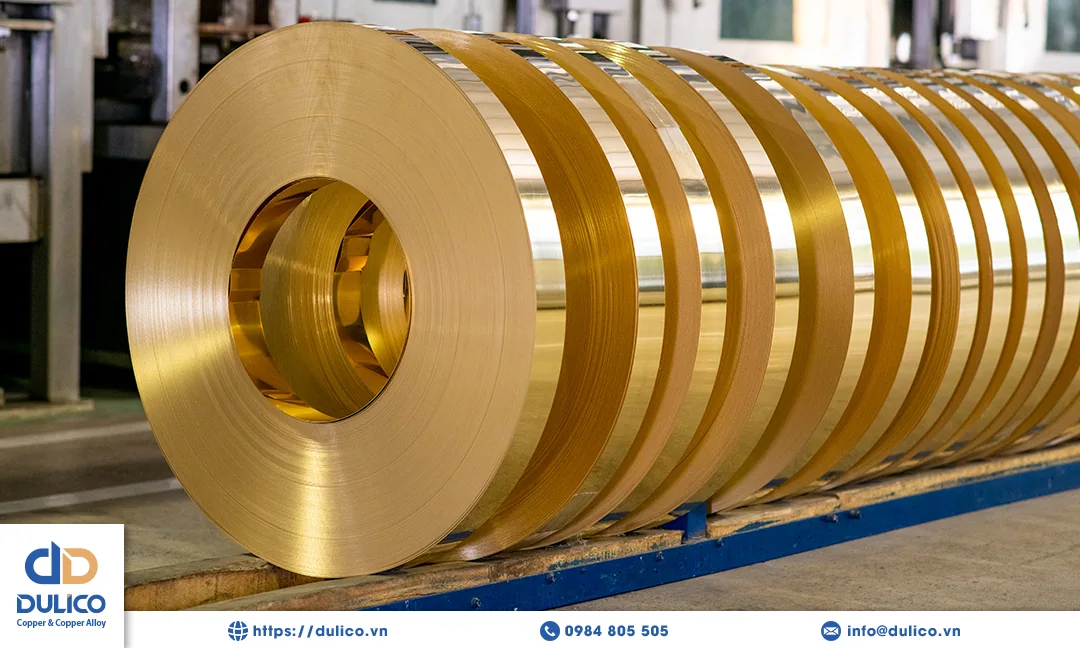

DULICO – A pioneer in producing brass strip in Vietnam

DULICO – A pioneer in producing brass strip in VietnamAs a pioneer in the production of brass strip in Vietnam, DULICO is proud to offer high-quality products that meet...

Copper and Brass: A Comparison

Copper and Brass: A ComparisonIn the mechanical processing industry, copper and brass are two of the most commonly used metals. Depending on their composition,...

China Scraps 13% Export Tax Rebate on Copper and Aluminum – How Will Businesses Adapt?

China Scraps 13% Export Tax Rebate on Copper and Aluminum – How Will Businesses Adapt?China is preparing to implement a significant policy change effective December 1, 2024. The country will eliminate the 13% export...

To receive a quotation and detailed consultation on products and technical specifications, please contact:

| Mr. Doan Thanh Tung (David) International Sales 📞+84 975 441 115 ✉️ tung.doan@dulico.vn | Mr. Nguyen Trong Duy (LEO) Director ✉️ duy.nguyen@dulico.vn |