Copper & Brass Fittings

Copper & Brass Fittings Processing

Dulico specializes in providing processing services for copper and brass fittings used in the water supply, gas, and air industries.

With raw copper produced from our internal casting process, Dulico can effectively control product quality and costs.

Brass and copper fittings are precisely machined using modern CNC lathes, ensuring high accuracy and consistency. Dulico’s engineering team is ready to support with design and provide tailored solutions based on customer requirements.

Quality and performance management system

- ISO 9001, 5S, Kaizen, TPM, LEAN, JIT …

Machinery and Equipment System

With the installation of CNC lathes equipped with an automatic feeding system, DULICO is ready to provide CNC machining services for copper parts with high precision, meeting all customer requirements

CNC Machining Material Specifications

| Machine Type | Diameter Range (mm) | Workpiece Length Range | Material Type |

|---|---|---|---|

| CNC lathe with automatic feeding system | Ø4 – Ø6 | 3 meters | Long bars, Copper or Steel grades |

| Over Ø6 to Ø8 | 3 meters | ||

| Over Ø8 to Ø20 | 3 meters | ||

| Over Ø20 to Max Ø32 | Từ 1.5 to 3 meters |

Quality is the top priority at DULICO. We implement a strict quality control process following standards such as TPM and ISO 9001:2015, ensuring that every product meets stringent technical requirements. The precision levels of our products range from ±0.01mm to ±0.02mm.

CNC Turning Precision Levels

| Diameter Precision | Product Length (mm) | Product Length Tolerance | Material Type |

|---|---|---|---|

| Very high precision (±0.01mm) | From 0.5 to 80mm | ±0.02 | Long bars, copper or steel grade |

Machining Profile and Production Capacity

| Machining Profile | Productivity per machine/8 hours | Total productivity for 6 machines/8 hours | Material Type |

|---|---|---|---|

| Plain cylindrical parts, stepped parts without holes | 800 products | 4800 products | Long bars, copper or steel grade |

| Plain cylindrical parts, stepped parts with holes | 600 products | 3600 products | |

| Threaded parts | 350 products | 2100 products | |

| Total products manufactured per month | 91.000 products |

Applications of Copper AND BRASS FITTING

Copper and brass fitting manufactured by CNC turning have a wide range of applications across various industries.

Why Choose DULICO ?

Superior Quality

DULICO’s copper is cast and rolled with quality checks, featuring excellent corrosion resistance and high durability, resulting in outstanding products.

Product Variety

We have the capability to manufacture a wide range of copper accessories, from spray nozzles and drain valves to connectors, meeting the diverse needs of our customers.

Competitive Pricing

In addition to a strict quality control process to deliver the best products to customers, DULICO also maintains control over raw material sourcing, ensuring that our products are always competitively priced in the market.

At DULICO, we not only focus on quality but also aim to build long-lasting relationships with our customers through the value we provide. We are always ready to assist and promptly address any requests from our esteemed clients

To receive a quotation and detailed consultation on products and technical specifications, please contact:

| Mr. Doan Thanh Tung (David) International Sales 📞+84 975 441 115 ✉️ tung.doan@dulico.vn | Mr. Nguyen Trong Duy (LEO) Director ✉️ duy.nguyen@dulico.vn |

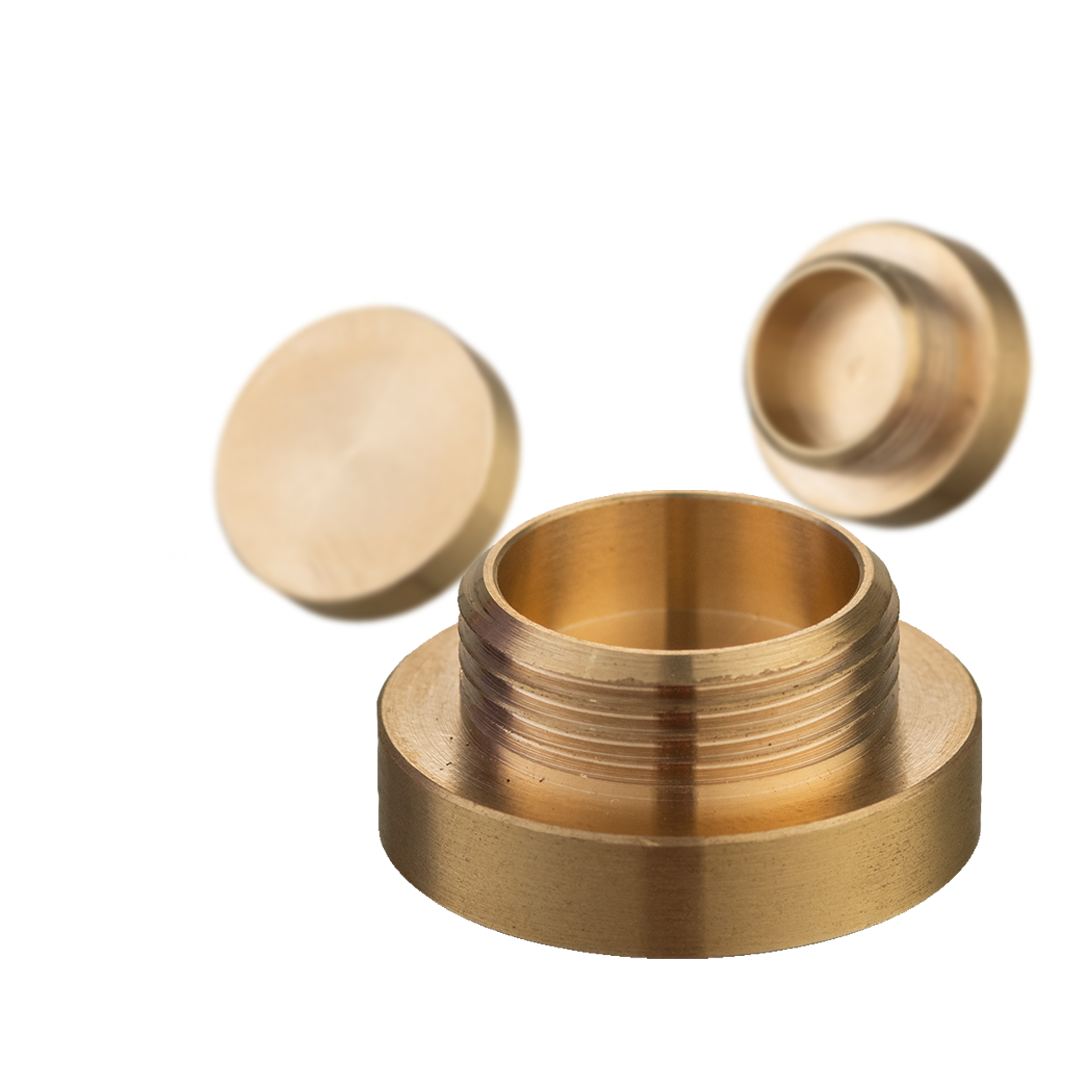

TYPICAL PRODUCTS

Copper & Brass Fitting 05

Material: Brass C2600, C2680... - Manufacturing Technology: CNC

Copper & Brass Fitting 02

Material: Brass C2600, C2680... - Manufacturing Technology: CNC

Copper & Brass Fitting 06

Material: Brass C2600, C2680... - Manufacturing Technology: CNC

Copper & Brass Fitting 04

Material: Brass C2600, C2680... - Manufacturing Technology: CNC

Copper & Brass Fitting 03

Material: Brass C2600, C2680... - Manufacturing Technology: CNC

Copper & Brass Fitting 01

Material: Brass C2600, C2680... - Manufacturing Technology: CNC