Product Specifications

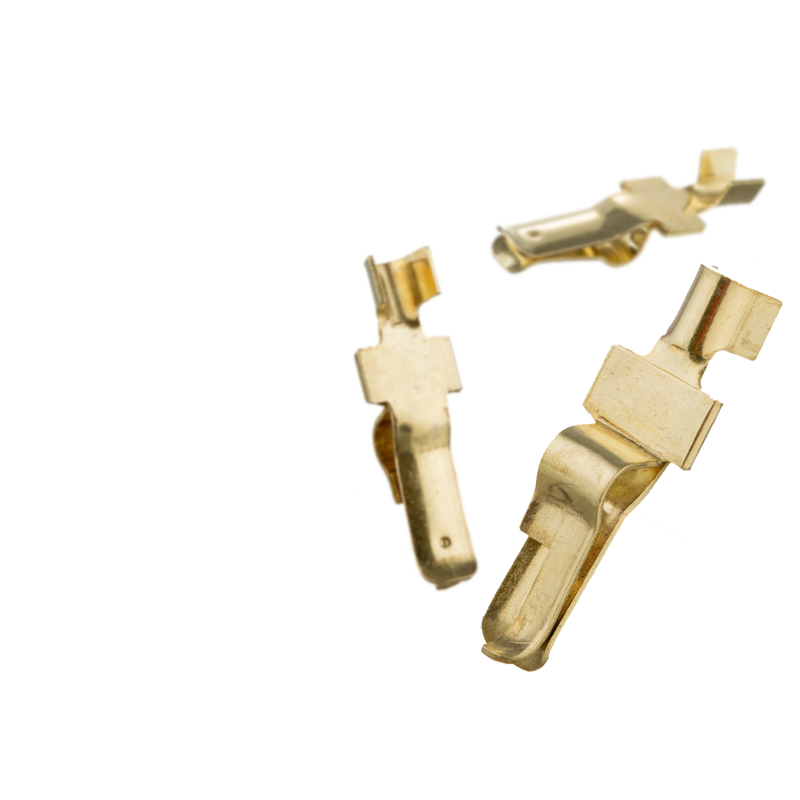

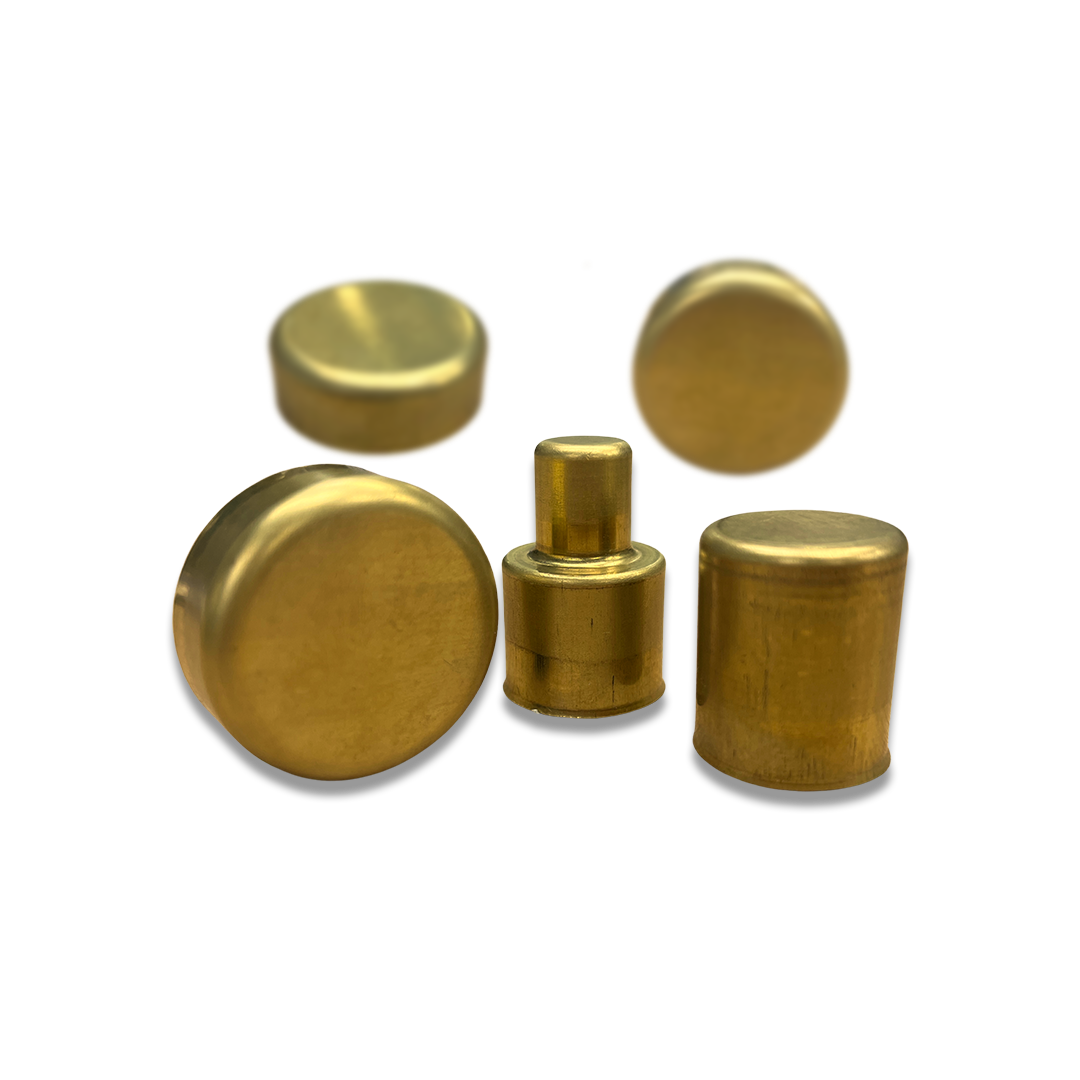

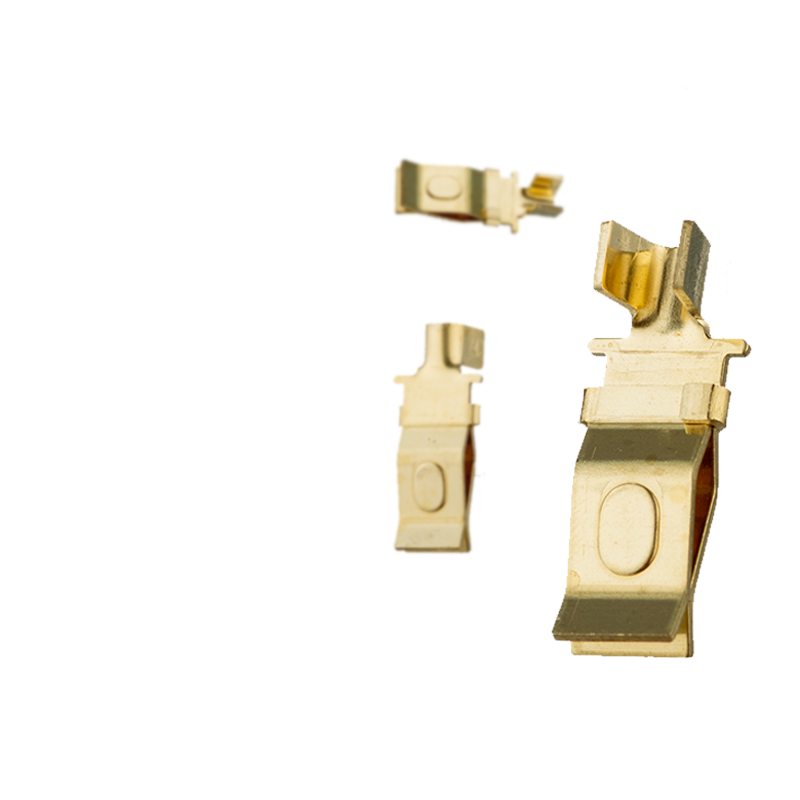

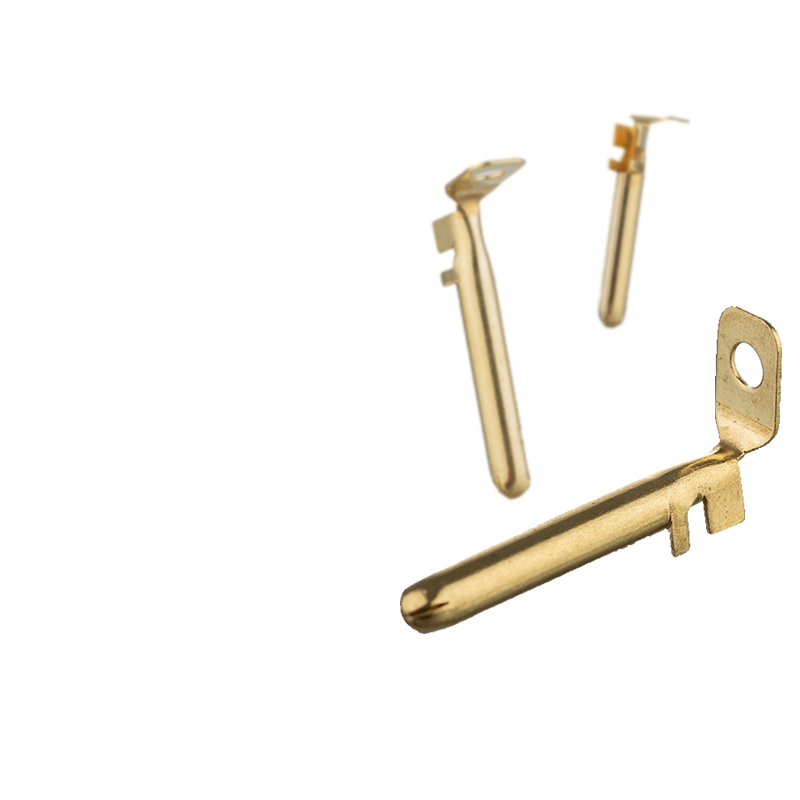

| Product Code | OEM / Custom-made | Material Codes | C1100, C2680, C2600 |

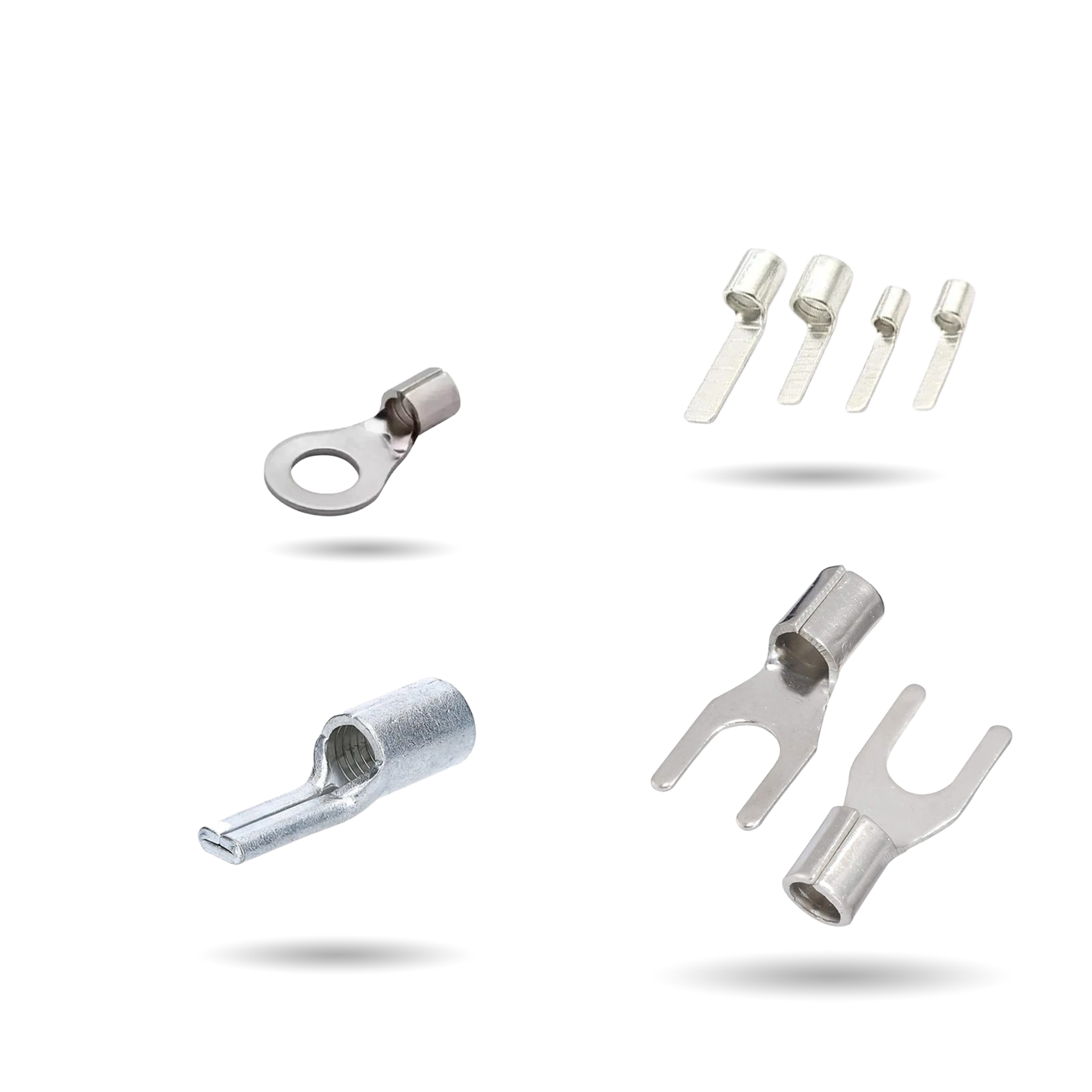

| Manufacturing Processes | Stamping, deep drawing, cup forming, tube rolling, punching | Minimum Order Quantity (MOQ) | 10,000 – 30,000 pcs (depending on part complexity & tooling) |

| Surface Finishing | Tin plating (Sn), nickel plating (Ni), or bare finish | Thickness (mm) | – |

| Production Standards | RoHS compliant, ISO 9001:2015 | Dimensional Tolerances (mm) | – |

Dulico’s copper lugs and crimp terminals are used across industrial electrical systems, power and renewable-energy equipment, household electrical appliances, residential wiring, and electric-vehicle related components.

Dulico Manufacturing Capabilities

- Copper bar and copper plate machining from 1–10 mm thickness, including stamping, forming, bending, and plating

- High-volume OEM production for electrical and energy manufacturers

- Strict quality control ensuring stable tolerances, uniform surface/edge finishing, and compliance with technical drawings

- Material autonomy in copper, ensuring price stability and reliable production lead time

To receive a quotation and detailed consultation on products and technical specifications, please contact:

| Mr. Doan Thanh Tung (David) International Sales 📞+84 975 441 115 ✉️ tung.doan@dulico.vn | Mr. Nguyen Trong Duy (LEO) Director ✉️ duy.nguyen@dulico.vn |